ANSYS APDL interactive control examples#

这些示例演示了如何将现有 ANSYS APDL 脚本转换为 Python PyMAPDL 脚本。

您也可以简单地使用 ansys-mapdl-core 中内置的 convert_script() 函数来转换现有的输入文件。

>>> from ansys.mapdl.core import convert_script

>>> inputfile = "ansys_inputfile.inp"

>>> pyscript = "pyscript.py"

>>> convert_script(inputfile, pyscript)

使用 SURF154 单元在杆件上施加扭转载荷#

此 Ansys APDL 脚本使用 SURF154 单元构建一根杆并对其施加扭矩。这是一个静态分析示例。

脚本初始化#

下面是 MAPDL 脚本的开头:

!----------------------------------------

! Input torque applied (moment)

! Input radius, height, element size...

!----------------------------------------

TORQUE = 100

RADIUS = 2

H_TIP = 2

HEIGHT = 20

ELEMSIZE = 1

PI = acos(-1)

FORCE = 100/RADIUS

PRESSURE = FORCE/(H_TIP*2*PI*RADIUS)

下面是相应的 PyMAPDL 脚本,包括初始化 Mapdl 类的实例:

import os

import numpy as np

from ansys.mapdl.core import launch_mapdl

# 在当前工作目录下启动 Ansys,默认工作名称为 "file"

mapdl = launch_mapdl(run_location=os.getcwd())

# 定义圆柱体和网格参数

torque = 100

radius = 2

h_tip = 2

height = 20

elemsize = 0.5

pi = np.arccos(-1)

force = 100 / radius

pressure = force / (h_tip * 2 * np.pi * radius)

创建模型#

下面是创建模型的 APDL 脚本:

!----------------------------------------

! Define higher-order SOLID186

! Define surface effect elements SURF154

! which is used to apply torque

! as a tangential pressure

!----------------------------------------

/prep7

et, 1, 186

et, 2, 154

r,1,

r,2,

!----------------------------------------

! Aluminum properties (or something)

!----------------------------------------

mp,ex,1,10e6

mp,nuxy,1,.3

mp,dens,1,.1/386.1

mp,dens,2,0

!----------------------------------------

! Simple cylinder

!----------------------------------------

*do, ICOUNT, 1, 4

cylind,RADIUS,,HEIGHTH_TIP,HEIGHT,90*(ICOUNT-1),90*ICOUNT

*enddo

nummrg,kp

lsel,s,loc,x,0

lsel,r,loc,y,0

lsel,r,loc,z,0,HEIGHT-H_TIP

lesize,all,ELEMSIZE*2

mshape,0

mshkey,1

esize,ELEMSIZE

allsel,all

VSWEEP, ALL

csys,1

asel,s,loc,z,HEIGHT-H_TIP+0.0001,HEIGHT0.0001

asel,r,loc,x,RADIUS

local,11,1

csys,0

aatt,2,2,2,11

amesh,all

finish

下面是相应的 PyMAPDL 脚本:

# Define higher-order SOLID186

# Define surface effect elements SURF154 to apply torque

# as a tangential pressure

mapdl.prep7()

mapdl.et(1, 186)

mapdl.et(2, 154)

mapdl.r(1)

mapdl.r(2)

# Aluminum properties (or something)

mapdl.mp("ex", 1, 10e6)

mapdl.mp("nuxy", 1, 0.3)

mapdl.mp("dens", 1, 0.1 / 386.1)

mapdl.mp("dens", 2, 0)

# Simple cylinder

for i in range(4):

mapdl.cylind(radius, "", "", height, 90 * (i - 1), 90 * i)

mapdl.nummrg("kp")

# interactive volume plot (optional)

mapdl.vplot()

# mesh cylinder

mapdl.lsel("s", "loc", "x", 0)

mapdl.lsel("r", "loc", "y", 0)

mapdl.lsel("r", "loc", "z", 0, height - h_tip)

mapdl.lesize("all", elemsize * 2)

mapdl.mshape(0)

mapdl.mshkey(1)

mapdl.esize(elemsize)

mapdl.allsel("all")

mapdl.vsweep("ALL")

mapdl.csys(1)

mapdl.asel("s", "loc", "z", "", height - h_tip + 0.0001)

mapdl.asel("r", "loc", "x", radius)

mapdl.local(11, 1)

mapdl.csys(0)

mapdl.aatt(2, 2, 2, 11)

mapdl.amesh("all")

mapdl.finish()

# plot elements

mapdl.eplot()

求解#

下面是 APDL 脚本的求解:

/solu

antype,static,new

eqslv,pcg,1e-8

!----------------------------------------

! Apply tangential pressure

!----------------------------------------

esel,s,type,,2

sfe,all,2,pres,,PRESSURE

!----------------------------------------

! Constrain bottom of cylinder/rod

!----------------------------------------

asel,s,loc,z,0

nsla,s,1

d,all,all

allsel,all

/psf,pres,,2

/pbc,u,1

/title, Simple torsional example

solve

finish

/post1

set,last

fsum

esel,u,type,,2

SAVE

下面是相应的 PyMAPDL 脚本:

# new solution

mapdl.slashsolu() # Using Slash instead of / due to duplicate SOLU command

# ansys('/solu') # could also use this line

mapdl.antype("static", "new")

mapdl.eqslv("pcg", 1e-8)

# Apply tangential pressure

mapdl.esel("s", "type", "", 2)

mapdl.sfe("all", 2, "pres", "", pressure)

# Constrain bottom of cylinder/rod

mapdl.asel("s", "loc", "z", 0)

mapdl.nsla("s", 1)

mapdl.d("all", "all")

mapdl.allsel()

mapdl.psf("pres", "", 2)

mapdl.pbc("u", 1)

mapdl.solve()

使用 PyMAPDL 在 Python 中访问和绘制结果:

# access the result from the mapdl result

result = mapdl.result

# alternatively, open the result file using the path used in MAPDL

# from ansys.mapdl import reader as pymapdl_reader

# resultfile = os.path.join(mapdl.path, 'file.rst')

# result = pymapdl_reader.read_binary(resultfile)

# access element results as arrays

nnum, stress = result.nodal_stress(0)

element_stress, elemnum, enode = result.element_stress(0)

nodenum, stress = result.nodal_stress(0)

# plot interactively

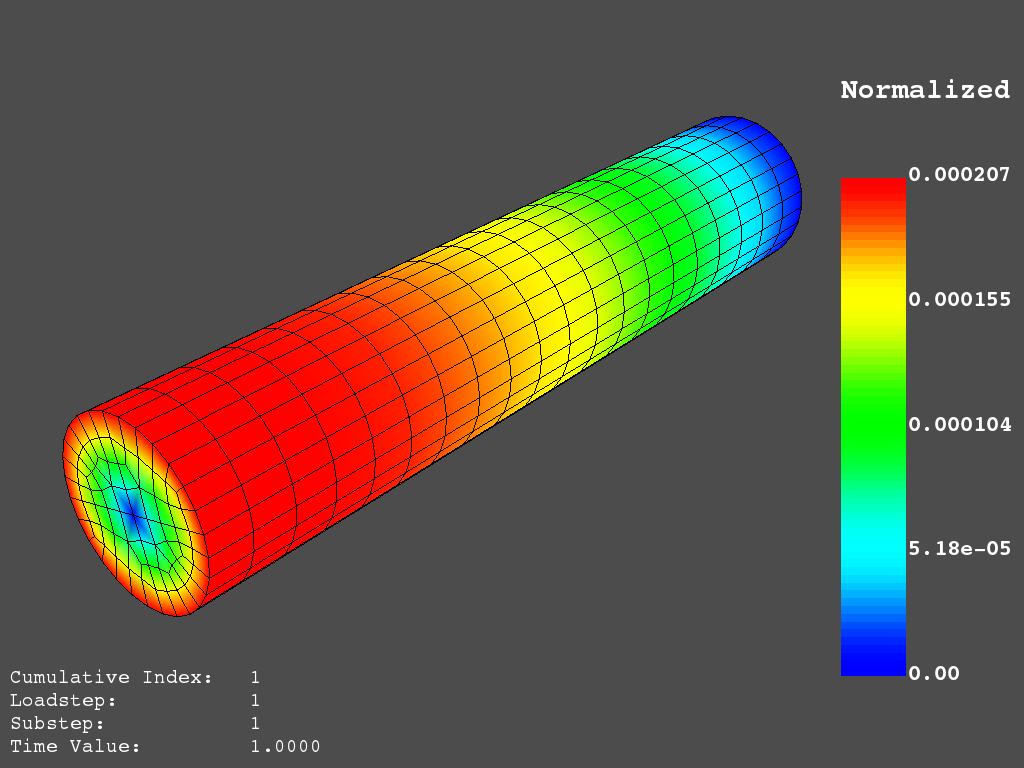

result.plot_nodal_solution(0, cmap="bwr")

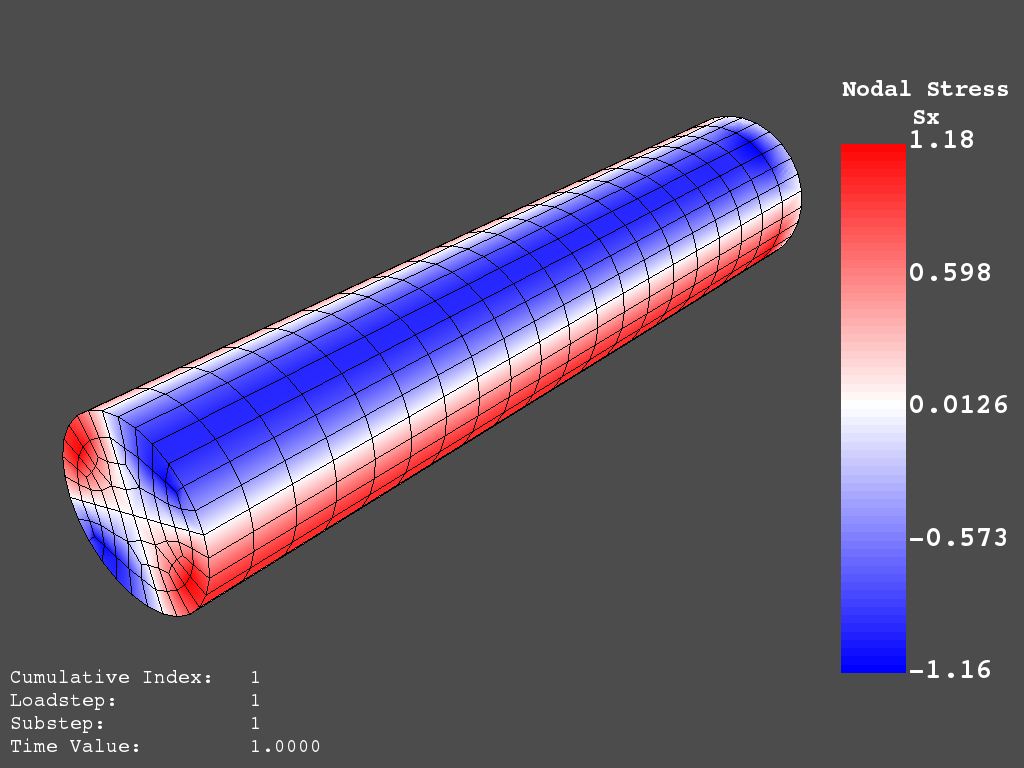

result.plot_nodal_stress(0, "Sx", cmap="bwr")

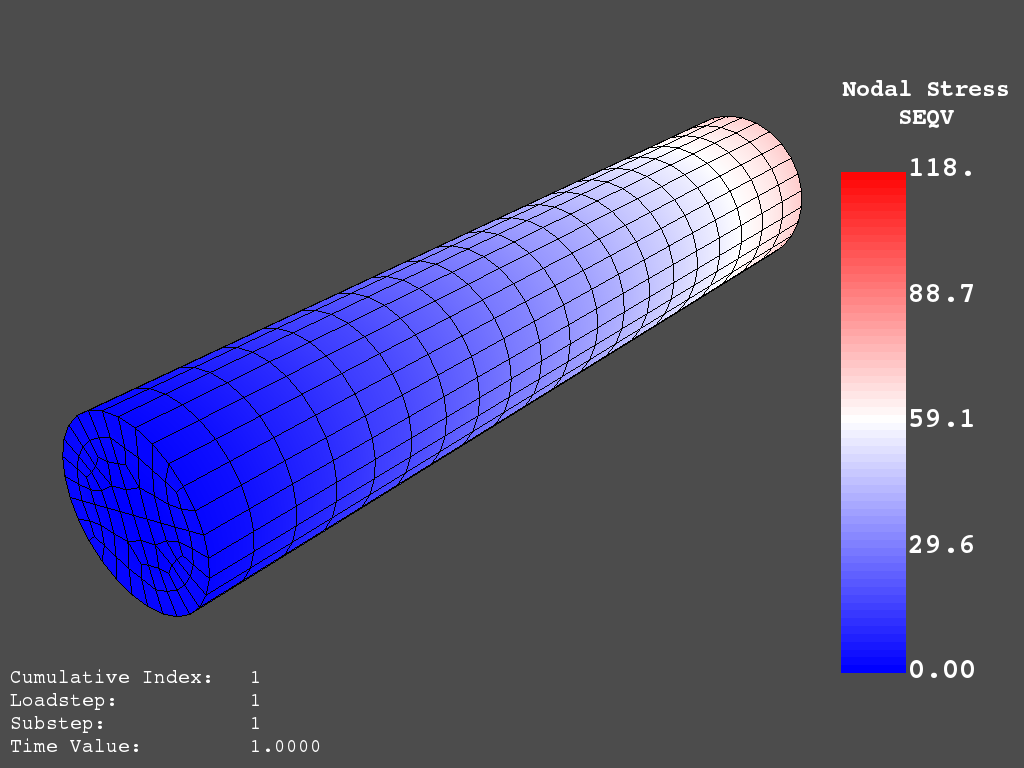

result.plot_principal_nodal_stress(0, "SEQV", cmap="bwr")

# plot and save non-interactively

# (cpos was output from ``cpos = result.plot()`` and setting up

# the correct camera angle)

cpos = [

(20.992831318277517, 9.78629316586435, 31.905115108541928),

(0.35955395443745797, -1.4198191001571547, 10.346158032932495),

(-0.10547549888485548, 0.9200673323892437, -0.377294345312956),

]

result.plot_nodal_displacement(0, cpos=cpos, savefig="cylinder_disp.png")

PyMAPDL 的位移结果的非交互式截图#

result.plot_nodal_stress(0, "Sx", cmap="bwr", cpos=cpos, screenshot="cylinder_sx.png")

PyMAPDL 中 X 应力的非交互式截图#

result.plot_principal_nodal_stress(

0, "SEQV", cmap="bwr", cpos=cpos, screenshot="cylinder_vonmises.png"

)

PyMAPDL 的 von Mises 应力非交互式截图#

您也可以使用 Mapdl.post_processing 属性直接从 MAPDL 访问相同的结果:

mapdl.set(1, 1)

mapdl.post_processing.plot_nodal_displacement()

result.plot_nodal_component_stress(0, "Sx")

result.plot_nodal_eqv_stress()

运行输入文件–“点焊 SHELL181” 示例#

这个 MAPDL 示例演示了如何对三片薄金属板进行点焊连接建模。在这里,只需使用 PyMAPDL 界面运行完整的输入文件。

!----------------------------------------

! Example problem for demonstrating

! Spotweld technology

!----------------------------------------

!

!----------------------------------------

! Originated in 9.0 JJDoyle 2004/09/01

!----------------------------------------

/prep7

/num,0

/pnum,area,1

k,1,2,10,

k,2,10,10

k,3,10,0.15

k,4,14,0.15

!

l,1,2

l,2,3

l,3,4

lfillt,1,2,3

lfillt,2,3,2

!

k,9,,

k,10,11,

k,11,15,

l,9,10

l,10,11

k,12,,10

lsel,s,,,6,7

AROTAT,all,,,,,,9,12,12,1,

lsel,s,,,1,5

AROTAT,all,,,,,,9,12,12,1,

areverse,1

areverse,2

asel,s,,,3,7

ARSYM,Y,all, , , ,0,0

allsel

!********

!define weld location with hardpoint

!********

HPTCREATE,AREA,7,0,COORD,12.9,0.15,-1.36,

/view,1,1,1,1

gplo

!

et,1,181

r,1,0.15

r,2,0.1

!

mp,ex,1,30e6

mp,prxy,1,0.3

!

esize,0.25

real,1

amesh,1

amesh,2

real,2

asel,s,,,3,12

amesh,all

!

lsel,s,,,1,9

lsel,a,,,12,17

lsel,a,,,26,38,3

lsel,a,,,24,36,3

nsll,s,1

wpstyle,0.05,0.1,-1,1,0.003,0,0,,5

WPSTYLE,,,,,,,,1

wpro,,-90.000000,

CSWPLA,11,1,1,1,

csys,11

nrotat,all

d,all,uy

d,all,rotx

csys,0

lsel,s,,,23

nsll,s,1

d,all,uz

lsel,s,,,17

nsll,s,1

d,all,uz,4

ALLSEL

/view,1,1,1,1

/eshape,1

ksel,s,,,33

nslk,s,1

*get,sw_node,node,,num,max

/solu

allsel

nlgeom,on

time,4

nsubst,10,25,5

outres,all,all

fini

!------------------------------------

!build flex spotweld with BEAM188, run the solution,

!and post process results

!------------------------------------

fini

allsel

/prep7

mp,ex,2,28e6

mp,prxy,2,0.3

!

SECTYPE,2,beam,csolid

SECDATA,0.25

!

et,2,188

type,2

mat,2

secnum,2

SWGEN,sweld1,0.50,7,2,sw_node,,

SWADD,sweld1,,12

/solu

allsel

nlgeom,on

time,4

nsubst,10,25,5

outres,all,all

solve

FINISH

>>> from ansys.mapdl.core import launch_mapdl

>>> mapdl = launch_mapdl()

>>> mapdl.input("spot_weld.inp")

下面是使用 ansys-mapdl-reader 软件包访问运行 MAPDL 分析后结果的 Python 脚本。

>>> from ansys.mapdl import reader as pymapdl_reader

打开结果文件,绘制 时间步 = 3 的位移图

>>> resultfile = os.path.join(mapdl.directory, "file.rst")

>>> result = pymapdl_reader.read_binary(resultfile)

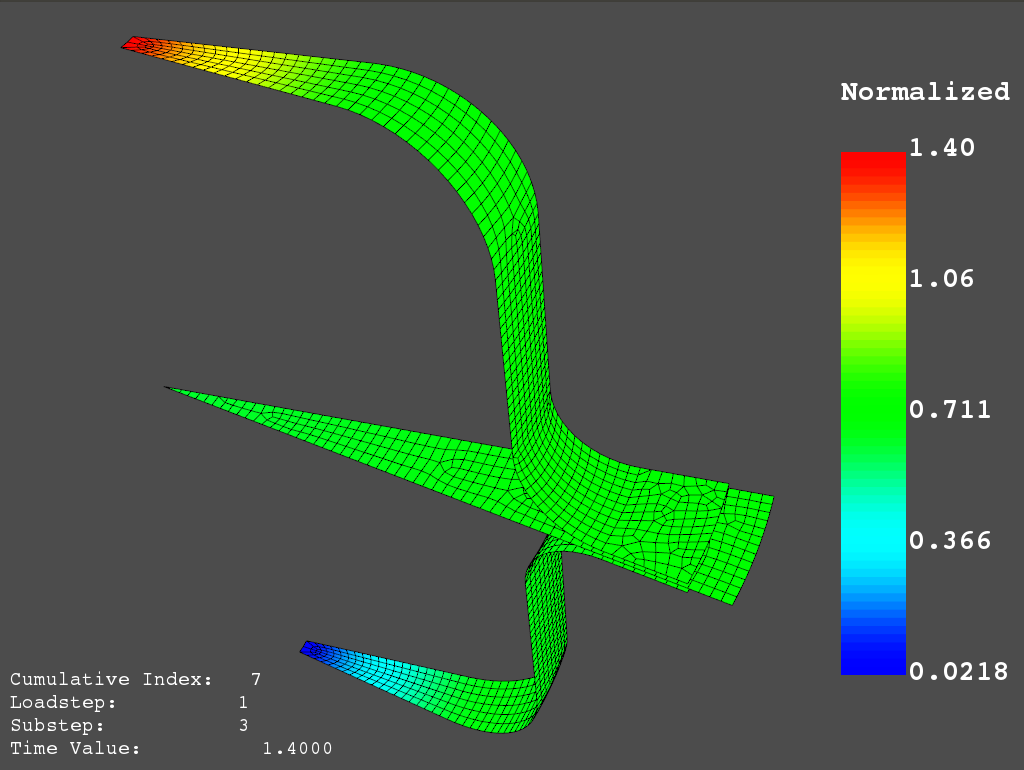

>>> result.plot_nodal_solution(2)

Spot Weld: Displacement#

获取 时间步 = 0 时的节点和单元分量应力。绘制 Z 方向的应力图。

>>> nodenum, stress = result.nodal_stress(0)

>>> element_stress, elemnum, enode = result.element_stress(0)

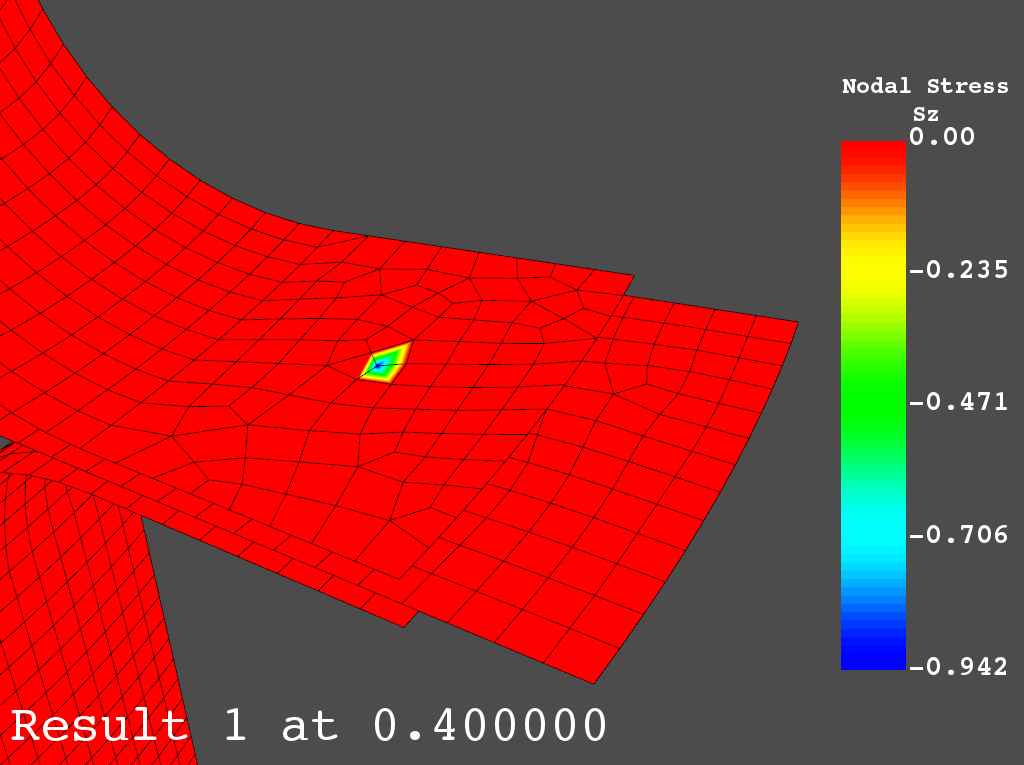

绘制 Z 方向应力图:模拟点焊的接触单元上的应力

>>> result.plot_nodal_stress(0, "Sz")

Spot weld: Z stress#

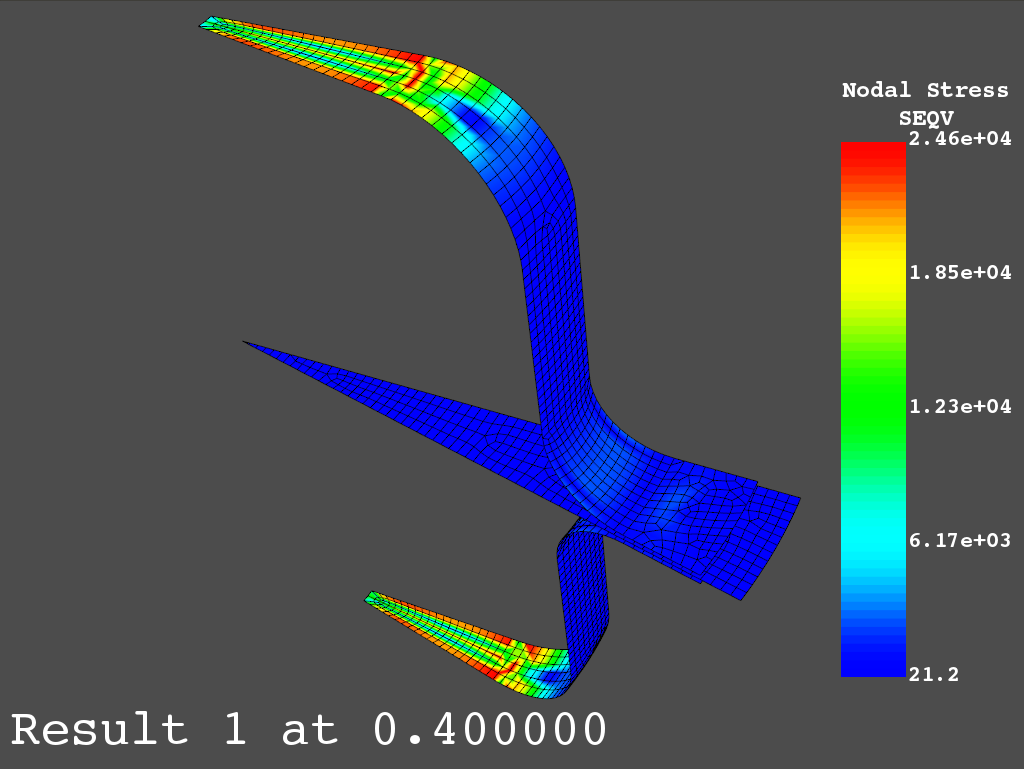

获取主节点应力并绘制 von Mises 应力图

>>> nnum, pstress = result.principal_nodal_stress(0)

>>> result.plot_principal_nodal_stress(0, "SEQV")

Spot weld: von Mises stress#