Note

Go to the end to download the full example code

PyVista 网格集成#

在 MAPDL 中对 pyvista 生成的网格进行模态分析。

import os

import tempfile

from ansys.mapdl.reader import save_as_archive

import pyvista as pv

from ansys.mapdl.core import launch_mapdl

# launch MAPDL as a service

mapdl = launch_mapdl(loglevel="ERROR")

# 在 XY 平面上创建一个以 (0, 0, 0) 为中心的简单平面网格

mesh = pv.Plane(i_resolution=100, j_resolution=100)

mesh.plot(color="w", show_edges=True)

将网格写入临时文件

archive_filename = os.path.join(tempfile.gettempdir(), "tmp.cdb")

save_as_archive(archive_filename, mesh)

# 读取存档文件

response = mapdl.cdread("db", archive_filename)

mapdl.prep7()

print(mapdl.shpp("SUMM"))

SUMMARIZE SHAPE TESTING FOR ALL SELECTED ELEMENTS

------------------------------------------------------------------------------

<<<<<< SHAPE TESTING SUMMARY >>>>>>

<<<<<< FOR ALL SELECTED ELEMENTS >>>>>>

------------------------------------------------------------------------------

--------------------------------------

| Element count 10000 SHELL181 |

--------------------------------------

Test Number tested Warning count Error count Warn+Err %

---- ------------- ------------- ----------- ----------

Aspect Ratio 10000 0 0 0.00 %

Parallel Deviation 10000 0 0 0.00 %

Maximum Angle 10000 0 0 0.00 %

Jacobian Ratio 10000 0 0 0.00 %

Warping Factor 10000 0 0 0.00 %

Any 10000 0 0 0.00 %

------------------------------------------------------------------------------

指定壳单元厚度

mapdl.sectype(1, "shell")

mapdl.secdata(0.01)

mapdl.emodif("ALL", "SECNUM", 1)

MODIFY ALL SELECTED ELEMENTS TO HAVE SECN = 1

规定材料属性 使用 AISI 5000 系列钢材的近似值

mapdl.units("SI") # not necessary, but helpful for book keeping

mapdl.mp("EX", 1, 200e9) # Elastic moduli in Pa (kg/(m*s**2))

mapdl.mp("DENS", 1, 7800) # Density in kg/m3

mapdl.mp("NUXY", 1, 0.3) # Poissons Ratio

mapdl.emodif("ALL", "MAT", 1)

MODIFY ALL SELECTED ELEMENTS TO HAVE MAT = 1

运行无约束模态分析 for the first 20 modes above 1 Hz

mapdl.modal_analysis(nmode=20, freqb=1)

# 您还可以这样运行:

# mapdl.run('/SOLU')

# mapdl.antype('MODAL') # default NEW

# mapdl.modopt('LANB', 20, 1)

# mapdl.solve()

*** NOTE *** CP = 7.734 TIME= 23:59:26

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 2 processes per solution.

***** MAPDL SOLVE COMMAND *****

*** NOTE *** CP = 7.734 TIME= 23:59:26

There is no title defined for this analysis.

*** NOTE *** CP = 7.734 TIME= 23:59:26

No modes are being expanded (MXPAND command) and therefore the element

results will not be written to the mode file. If you do not intend to

use mode selection and for more efficient calculation of element

results in the expansion pass of any downstream mode superposition

analyses, expand all modes during the modal analysis.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

---GIVE SUGGESTIONS ONLY---

ELEMENT TYPE 4 IS SHELL181. IT IS ASSOCIATED WITH ELASTOPLASTIC

MATERIALS ONLY. KEYOPT(8)=2 IS SUGGESTED AND KEYOPT(3)=2 IS SUGGESTED FOR

HIGHER ACCURACY OF MEMBRANE STRESSES; OTHERWISE, KEYOPT(3)=0 IS SUGGESTED.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***

Ansys Mechanical Enterprise

20120530 VERSION=WINDOWS x64 23:59:26 JAN 25, 2024 CP= 7.734

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ ROTX ROTY ROTZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .MODAL

EXTRACTION METHOD. . . . . . . . . . . . . .BLOCK LANCZOS

NUMBER OF MODES TO EXTRACT. . . . . . . . . . . 20

SHIFT POINT . . . . . . . . . . . . . . . . . . 1.0000

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** WARNING *** CP = 7.766 TIME= 23:59:26

No constraints have been defined using the D command.

*** NOTE *** CP = 7.766 TIME= 23:59:26

The step data was checked and warning messages were found.

Please review output or errors file (

C:\Users\ff\AppData\Local\Temp\ansys_orzczjzgnq\file0.err ) for these

warning messages.

*** NOTE *** CP = 7.766 TIME= 23:59:26

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 10000

...Number of nodes: 10201

...Decompose to 2 CPU domains

...Element load balance ratio = 1.000

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

THERMAL STRAINS INCLUDED IN THE LOAD VECTOR . . YES

*********** PRECISE MASS SUMMARY ***********

TOTAL RIGID BODY MASS MATRIX ABOUT ORIGIN

Translational mass | Coupled translational/rotational mass

78.000 0.0000 0.0000 | 0.0000 0.0000 0.11102E-15

0.0000 78.000 0.0000 | 0.0000 0.0000 0.35527E-14

0.0000 0.0000 78.000 | -0.66613E-15 -0.35527E-14 0.0000

------------------------------------------ | ------------------------------------------

| Rotational mass (inertia)

| 6.5006 0.34694E-15 0.0000

| 0.17000E-15 6.5006 0.0000

| 0.0000 0.0000 12.999

TOTAL MASS = 78.000

The mass principal axes coincide with the global Cartesian axes

CENTER OF MASS (X,Y,Z)= 0.45548E-16 -0.14234E-17 0.0000

TOTAL INERTIA ABOUT CENTER OF MASS

6.5006 0.34694E-15 0.0000

0.34694E-15 6.5006 0.0000

0.0000 0.0000 12.999

The inertia principal axes coincide with the global Cartesian axes

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

4 78.0000

Range of element maximum matrix coefficients in global coordinates

Maximum = 749504998 at element 9585.

Minimum = 749503915 at element 9596.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

4 10000 SHELL181 0.281 0.000028

Time at end of element matrix formulation CP = 7.96875.

BLOCK LANCZOS CALCULATION OF UP TO 20 EIGENVECTORS.

NUMBER OF EQUATIONS = 61206

MAXIMUM WAVEFRONT = 26

MAXIMUM MODES STORED = 20

MINIMUM EIGENVALUE = 0.10000E+01

MAXIMUM EIGENVALUE = 0.10000E+31

Process memory allocated for solver = 66.697 MB

Process memory required for in-core solution = 63.679 MB

Process memory required for out-of-core solution = 30.081 MB

Total memory allocated for solver = 132.847 MB

Total memory required for in-core solution = 126.837 MB

Total memory required for out-of-core solution = 58.694 MB

*** NOTE *** CP = 8.328 TIME= 23:59:27

The Distributed Sparse Matrix Solver used by the Block Lanczos

eigensolver is currently running in the in-core memory mode. This

memory mode uses the most amount of memory in order to avoid using the

hard drive as much as possible, which most often results in the

fastest solution time. This mode is recommended if enough physical

memory is present to accommodate all of the solver data.

Total memory available for LANCZOS = 39.727852 GB

Process memory required for in-core LANCZOS Workspace = 122.022560 MB

Process memory required for out-of-core LANCZOS Workspace = 3.376808 MB

Total memory required for in-core LANCZOS Workspace = 241.530350 MB

Total memory required for out-of-core LANCZOS Workspace = 6.693741 MB

Lanczos Memory Mode : INCORE

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***

Ansys Mechanical Enterprise

20120530 VERSION=WINDOWS x64 23:59:28 JAN 25, 2024 CP= 8.609

*** FREQUENCIES FROM BLOCK LANCZOS ITERATION ***

MODE FREQUENCY (HERTZ)

FREQUENCY RANGE REQUESTED= 20 MODES ABOVE 1.00000 HERTZ

1 32.74664192913

2 47.77804288706

3 59.17108298309

4 84.60790505091

5 84.60790505194

6 148.8927748644

7 148.8927748649

8 154.6519861755

9 168.3840411456

10 187.7790667336

11 255.9751634910

12 255.9751634923

13 285.2444050784

14 298.2943388358

15 319.8023401629

16 319.8023401639

17 370.6023621795

18 391.8457651354

19 409.1039880837

20 482.6516135507

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***

Ansys Mechanical Enterprise

20120530 VERSION=WINDOWS x64 23:59:28 JAN 25, 2024 CP= 8.609

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 32.7466 0.30537E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 47.7780 0.20930E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 59.1711 0.16900E-01 0.0000 0.000000 0.00000 0.00000 0.00000

4 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

5 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

6 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 154.652 0.64661E-02 0.0000 0.000000 0.00000 0.00000 0.00000

9 168.384 0.59388E-02 0.0000 0.000000 0.00000 0.00000 0.00000

10 187.779 0.53254E-02 0.0000 0.000000 0.00000 0.00000 0.00000

11 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

12 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

13 285.244 0.35058E-02 0.0000 0.000000 0.00000 0.00000 0.00000

14 298.294 0.33524E-02 0.0000 0.000000 0.00000 0.00000 0.00000

15 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

16 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

17 370.602 0.26983E-02 0.0000 0.000000 0.00000 0.00000 0.00000

18 391.846 0.25520E-02 0.0000 0.000000 0.00000 0.00000 0.00000

19 409.104 0.24444E-02 0.0000 0.000000 0.00000 0.00000 0.00000

20 482.652 0.20719E-02 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 32.7466 0.30537E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 47.7780 0.20930E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 59.1711 0.16900E-01 0.0000 0.000000 0.00000 0.00000 0.00000

4 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

5 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

6 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 154.652 0.64661E-02 0.0000 0.000000 0.00000 0.00000 0.00000

9 168.384 0.59388E-02 0.0000 0.000000 0.00000 0.00000 0.00000

10 187.779 0.53254E-02 0.0000 0.000000 0.00000 0.00000 0.00000

11 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

12 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

13 285.244 0.35058E-02 0.0000 0.000000 0.00000 0.00000 0.00000

14 298.294 0.33524E-02 0.0000 0.000000 0.00000 0.00000 0.00000

15 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

16 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

17 370.602 0.26983E-02 0.0000 0.000000 0.00000 0.00000 0.00000

18 391.846 0.25520E-02 0.0000 0.000000 0.00000 0.00000 0.00000

19 409.104 0.24444E-02 0.0000 0.000000 0.00000 0.00000 0.00000

20 482.652 0.20719E-02 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 32.7466 0.30537E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 47.7780 0.20930E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 59.1711 0.16900E-01 0.0000 0.000000 0.00000 0.00000 0.00000

4 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

5 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

6 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 154.652 0.64661E-02 0.0000 0.000000 0.00000 0.00000 0.00000

9 168.384 0.59388E-02 0.0000 0.000000 0.00000 0.00000 0.00000

10 187.779 0.53254E-02 0.0000 0.000000 0.00000 0.00000 0.00000

11 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

12 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

13 285.244 0.35058E-02 0.0000 0.000000 0.00000 0.00000 0.00000

14 298.294 0.33524E-02 0.0000 0.000000 0.00000 0.00000 0.00000

15 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

16 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

17 370.602 0.26983E-02 0.0000 0.000000 0.00000 0.00000 0.00000

18 391.846 0.25520E-02 0.0000 0.000000 0.00000 0.00000 0.00000

19 409.104 0.24444E-02 0.0000 0.000000 0.00000 0.00000 0.00000

20 482.652 0.20719E-02 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION *****ROTX DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 32.7466 0.30537E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 47.7780 0.20930E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 59.1711 0.16900E-01 0.0000 0.000000 0.00000 0.00000 0.00000

4 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

5 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

6 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 154.652 0.64661E-02 0.0000 0.000000 0.00000 0.00000 0.00000

9 168.384 0.59388E-02 0.0000 0.000000 0.00000 0.00000 0.00000

10 187.779 0.53254E-02 0.0000 0.000000 0.00000 0.00000 0.00000

11 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

12 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

13 285.244 0.35058E-02 0.0000 0.000000 0.00000 0.00000 0.00000

14 298.294 0.33524E-02 0.0000 0.000000 0.00000 0.00000 0.00000

15 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

16 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

17 370.602 0.26983E-02 0.0000 0.000000 0.00000 0.00000 0.00000

18 391.846 0.25520E-02 0.0000 0.000000 0.00000 0.00000 0.00000

19 409.104 0.24444E-02 0.0000 0.000000 0.00000 0.00000 0.00000

20 482.652 0.20719E-02 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION *****ROTY DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 32.7466 0.30537E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 47.7780 0.20930E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 59.1711 0.16900E-01 0.0000 0.000000 0.00000 0.00000 0.00000

4 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

5 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

6 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 154.652 0.64661E-02 0.0000 0.000000 0.00000 0.00000 0.00000

9 168.384 0.59388E-02 0.0000 0.000000 0.00000 0.00000 0.00000

10 187.779 0.53254E-02 0.0000 0.000000 0.00000 0.00000 0.00000

11 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

12 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

13 285.244 0.35058E-02 0.0000 0.000000 0.00000 0.00000 0.00000

14 298.294 0.33524E-02 0.0000 0.000000 0.00000 0.00000 0.00000

15 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

16 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

17 370.602 0.26983E-02 0.0000 0.000000 0.00000 0.00000 0.00000

18 391.846 0.25520E-02 0.0000 0.000000 0.00000 0.00000 0.00000

19 409.104 0.24444E-02 0.0000 0.000000 0.00000 0.00000 0.00000

20 482.652 0.20719E-02 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION *****ROTZ DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 32.7466 0.30537E-01 0.0000 0.000000 0.00000 0.00000 0.00000

2 47.7780 0.20930E-01 0.0000 0.000000 0.00000 0.00000 0.00000

3 59.1711 0.16900E-01 0.0000 0.000000 0.00000 0.00000 0.00000

4 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

5 84.6079 0.11819E-01 0.0000 0.000000 0.00000 0.00000 0.00000

6 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 148.893 0.67162E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 154.652 0.64661E-02 0.0000 0.000000 0.00000 0.00000 0.00000

9 168.384 0.59388E-02 0.0000 0.000000 0.00000 0.00000 0.00000

10 187.779 0.53254E-02 0.0000 0.000000 0.00000 0.00000 0.00000

11 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

12 255.975 0.39066E-02 0.0000 0.000000 0.00000 0.00000 0.00000

13 285.244 0.35058E-02 0.0000 0.000000 0.00000 0.00000 0.00000

14 298.294 0.33524E-02 0.0000 0.000000 0.00000 0.00000 0.00000

15 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

16 319.802 0.31269E-02 0.0000 0.000000 0.00000 0.00000 0.00000

17 370.602 0.26983E-02 0.0000 0.000000 0.00000 0.00000 0.00000

18 391.846 0.25520E-02 0.0000 0.000000 0.00000 0.00000 0.00000

19 409.104 0.24444E-02 0.0000 0.000000 0.00000 0.00000 0.00000

20 482.652 0.20719E-02 0.0000 0.000000 0.00000 0.00000 0.00000

*** MAPDL BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

8.625 MB WRITTEN ON ASSEMBLED MATRIX FILE: file0.full

1.125 MB WRITTEN ON MODAL MATRIX FILE: file0.mode

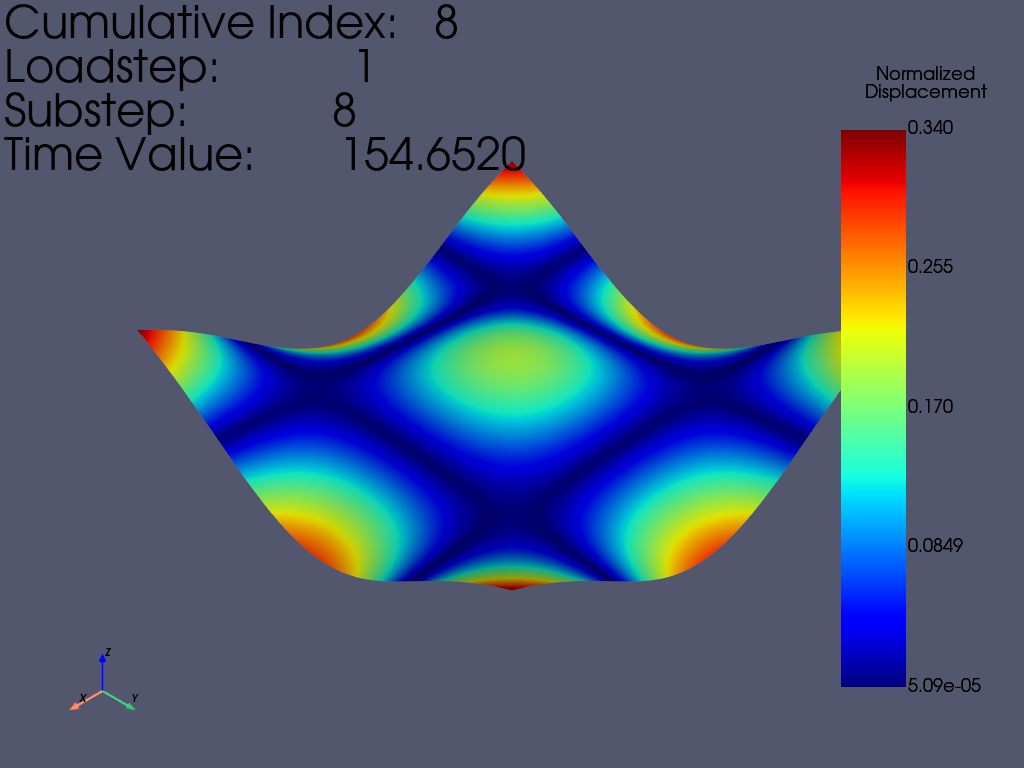

在 pyansys 中加载结果文件并绘制第 8 阶模态。

result = mapdl.result

print(result)

result.plot_nodal_displacement(7, show_displacement=True, displacement_factor=0.4)

PyMAPDL Result

Units : User Defined

Version : 23.1

Cyclic : False

Result Sets : 20

Nodes : 10201

Elements : 10000

Available Results:

NSL : Nodal displacements

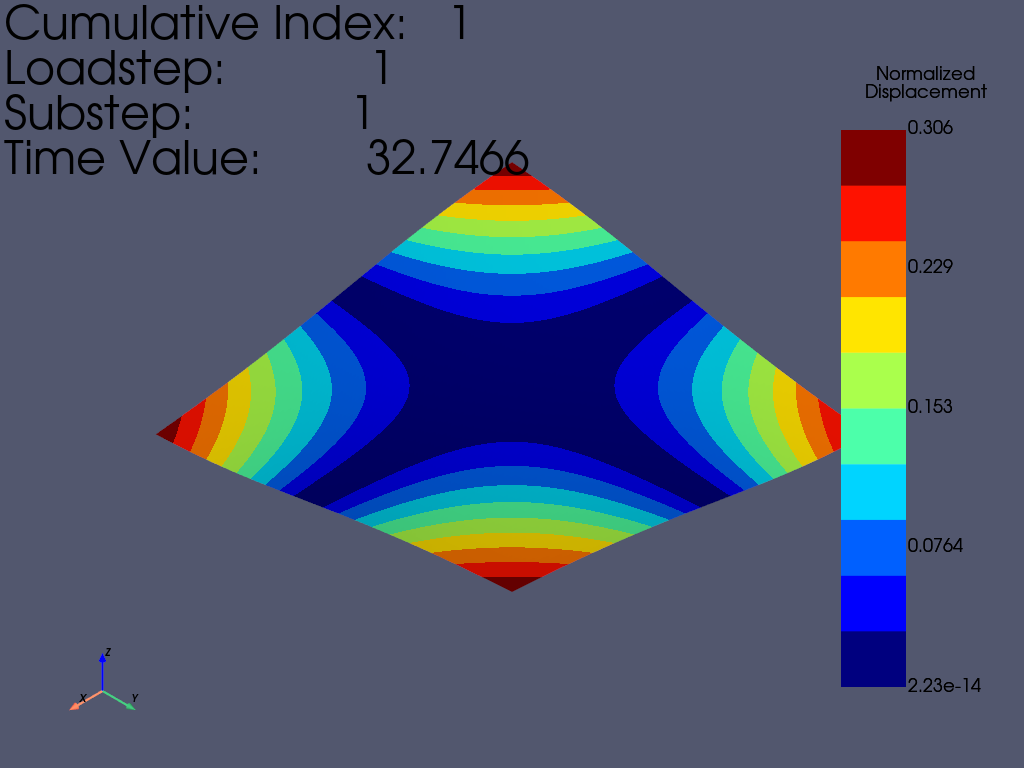

使用等高线绘制一阶模态

result.plot_nodal_displacement(

0, show_displacement=True, displacement_factor=0.4, n_colors=10

)

对模态分析结果进行动画处理

禁用 movie_filename ,并增加 n_frames 以获得更平滑的绘图。使用 loop=True 启用连续循环绘图。

result.animate_nodal_displacement(

18,

loop=False,

add_text=False,

n_frames=30,

displacement_factor=0.4,

show_axes=False,

background="w",

movie_filename="plane_vib.gif",

)

[(1.5773502691896262, 1.5773502691896262, 1.5773502691896262),

(0.0, 0.0, 0.0),

(0.0, 0.0, 1.0)]

Stop mapdl#

mapdl.exit()

Total running time of the script: (0 minutes 4.630 seconds)