Note

Go to the end to download the full example code

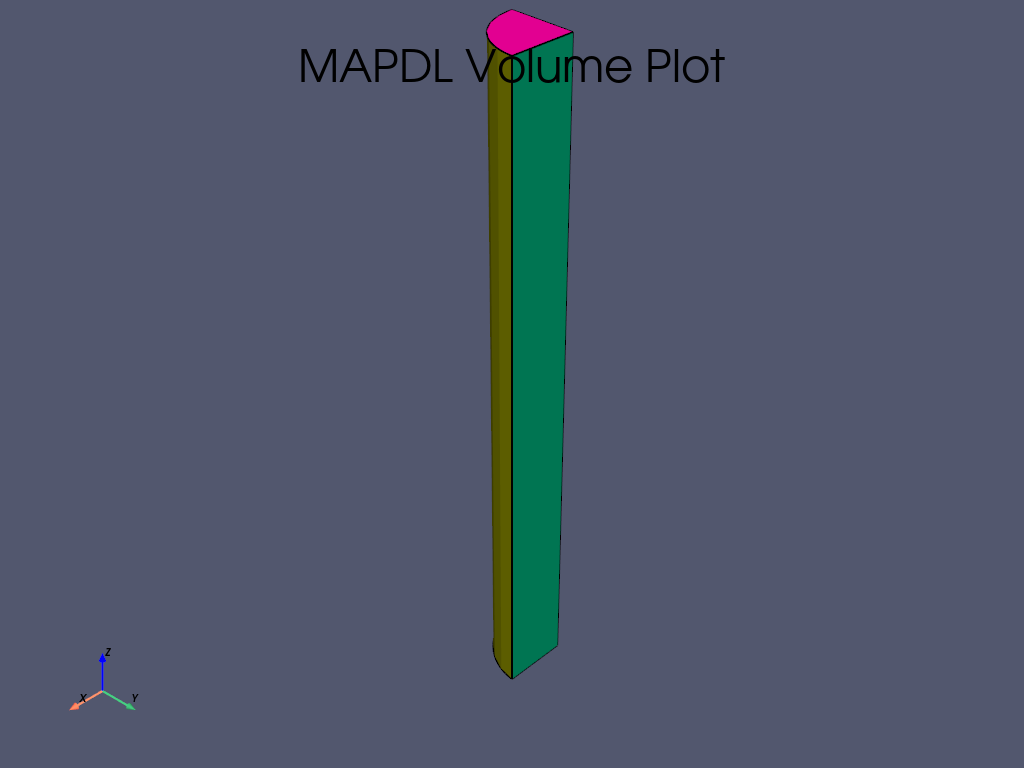

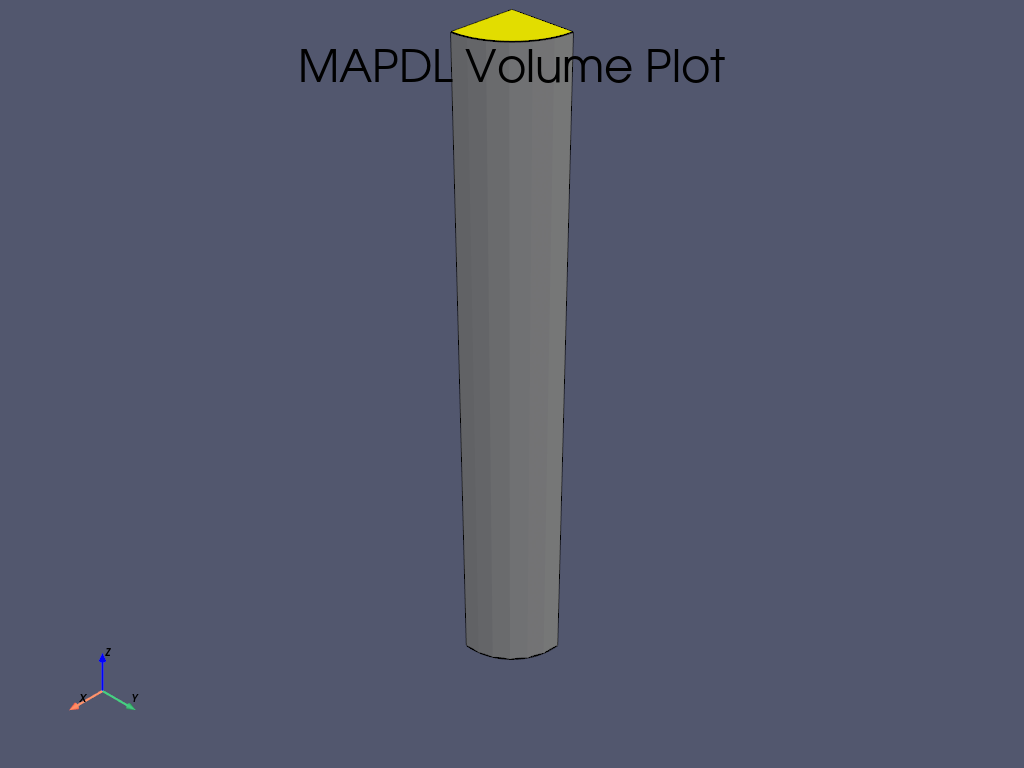

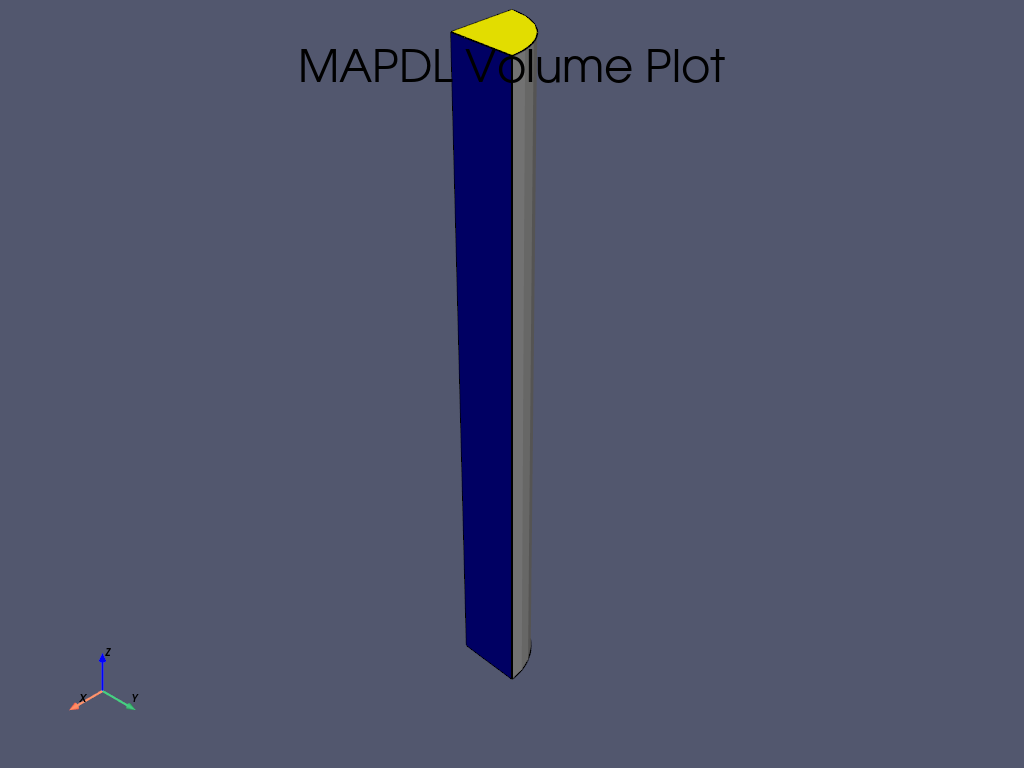

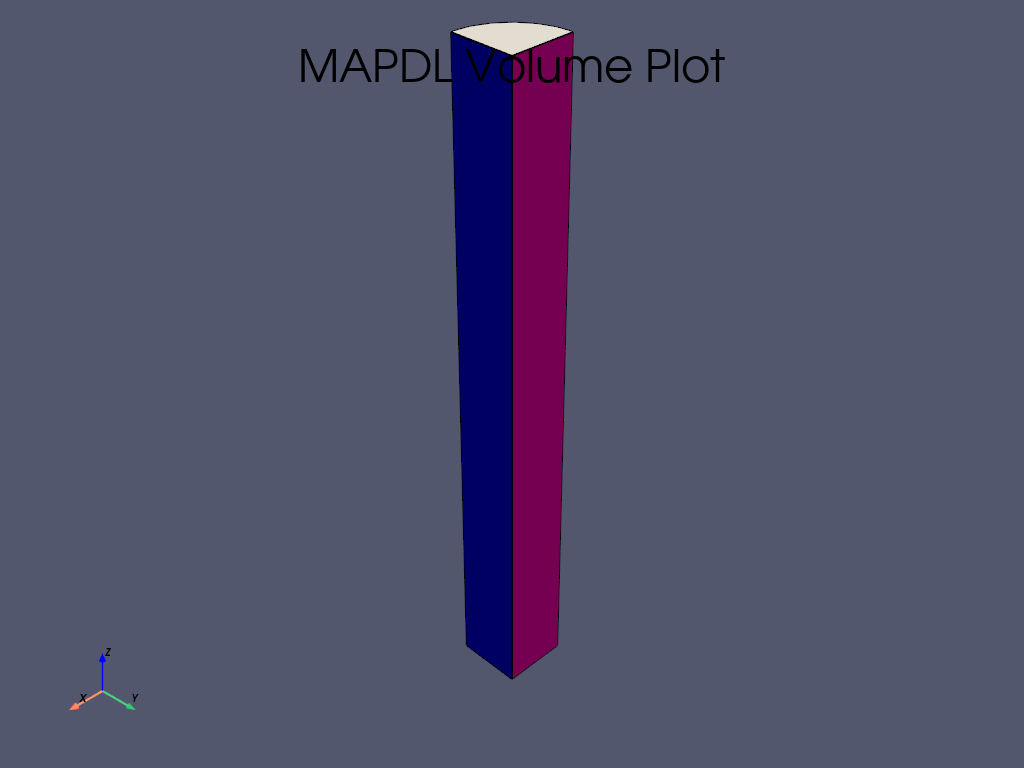

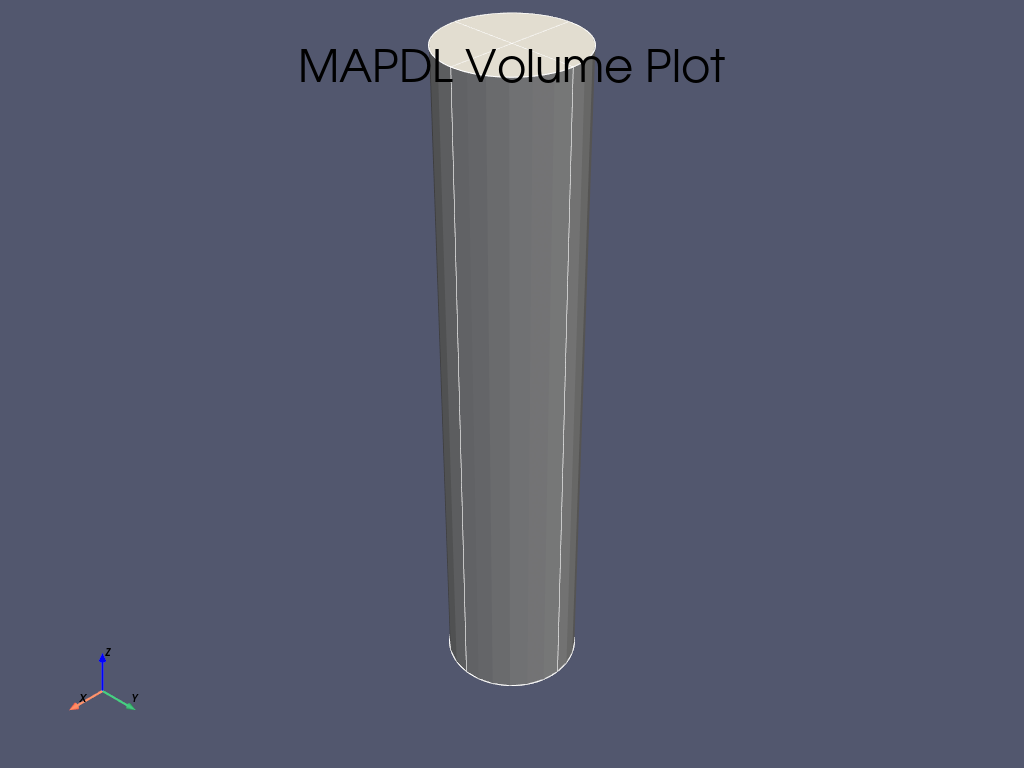

Torsional load on a bar using SURF154 elements#

This Ansys PyMAPDL script builds a bar and applies torque to it using SURF154 elements. This is a static analysis example.

Script initialization#

import os

import numpy as np

from ansys.mapdl.core import launch_mapdl

# start Ansys in the current working directory with default jobname "file"

mapdl = launch_mapdl(run_location=os.getcwd(), version=23.1)

Define cylinder and mesh parameters

Model creation#

# Define higher-order SOLID186

# Define surface effect elements SURF154 to apply torque

# as a tangential pressure

mapdl.prep7()

mapdl.et(1, 186)

mapdl.et(2, 154)

mapdl.r(1)

mapdl.r(2)

REAL CONSTANT SET 2 ITEMS 1 TO 6

0.0000 0.0000 0.0000 0.0000 0.0000 0.0000

Aluminum properties (or something)

Mesh cylinder

mapdl.lsel("s", "loc", "x", 0)

mapdl.lsel("r", "loc", "y", 0)

mapdl.lsel("r", "loc", "z", 0, height - h_tip)

mapdl.lesize("all", elemsize * 2)

mapdl.mshape(0)

mapdl.mshkey(1)

mapdl.esize(elemsize)

mapdl.allsel("all")

mapdl.vsweep("ALL")

mapdl.csys(1)

mapdl.asel("s", "loc", "z", "", height - h_tip + 0.0001)

mapdl.asel("r", "loc", "x", radius)

mapdl.local(11, 1)

mapdl.csys(0)

mapdl.aatt(2, 2, 2, 11)

mapdl.amesh("all")

mapdl.finish()

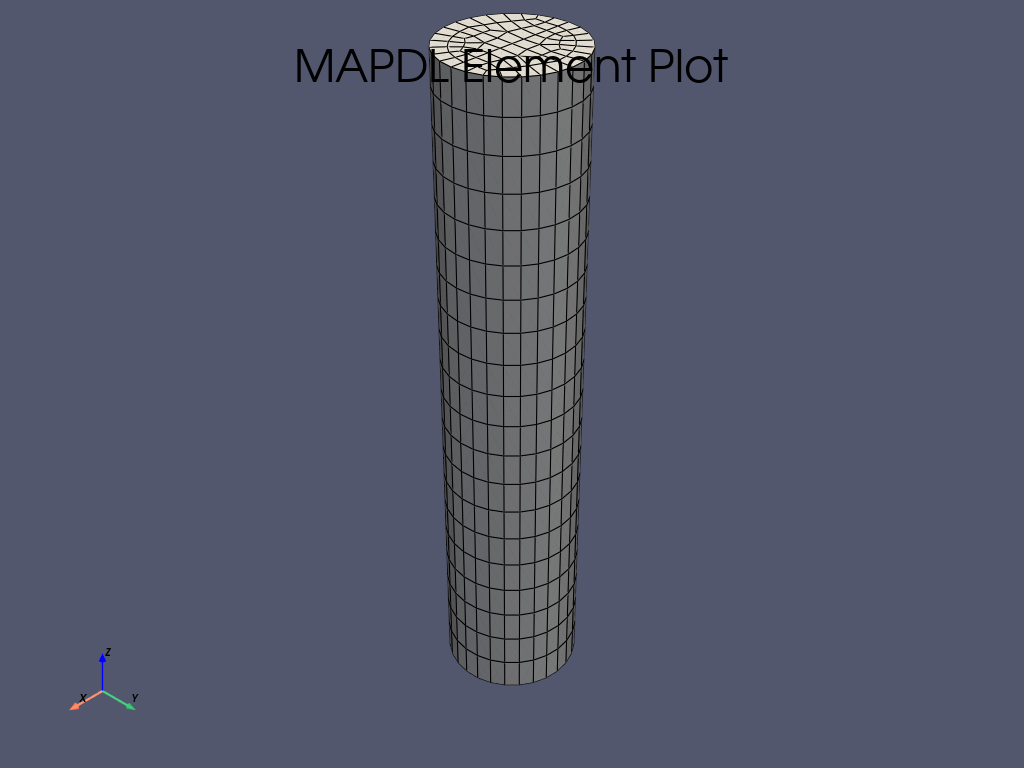

# plot elements

mapdl.eplot()

Solution#

mapdl.slashsolu() # Using Slash instead of / due to duplicate SOLU command

mapdl.antype("static", "new")

mapdl.eqslv("pcg", 1e-8)

# Apply tangential pressure

mapdl.esel("s", "type", "", 2)

mapdl.sfe("all", 2, "pres", "", pressure)

# Constrain bottom of cylinder/rod

mapdl.asel("s", "loc", "z", 0)

mapdl.nsla("s", 1)

mapdl.d("all", "all")

mapdl.allsel()

mapdl.psf("pres", "", 2)

mapdl.pbc("u", 1)

mapdl.solve()

*** NOTE *** CP = 2.891 TIME= 13:25:01

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 2 processes per solution.

***** MAPDL SOLVE COMMAND *****

*** NOTE *** CP = 2.891 TIME= 13:25:01

There is no title defined for this analysis.

*** WARNING *** CP = 2.891 TIME= 13:25:01

It has been detected that you are using reduced integration brick

elements along with the PCG solver (EQSLV,PCG). Please verify that

you have multiple elements through the thickness in your model or

switch to the SPARSE solver (EQSLV,SPARSE).

*** NOTE *** CP = 2.891 TIME= 13:25:01

The model data was checked and warning messages were found.

Please review output or errors file (

C:\Users\ff\AppData\Local\Temp\ansys_jfmaksbfrz\file0.err ) for these

warning messages.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

---GIVE SUGGESTIONS ONLY---

ELEMENT TYPE 1 IS SOLID186. KEYOPT(2) IS ALREADY SET AS SUGGESTED.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***

Ansys Mechanical Enterprise

20120530 VERSION=WINDOWS x64 13:25:01 MAR 15, 2024 CP= 2.891

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .STATIC (STEADY-STATE)

EQUATION SOLVER OPTION. . . . . . . . . . . . .PCG

TOLERANCE. . . . . . . . . . . . . . . . . . 1.00000E-08

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** NOTE *** CP = 2.891 TIME= 13:25:01

Present time 0 is less than or equal to the previous time. Time will

default to 1.

*** NOTE *** CP = 2.891 TIME= 13:25:01

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 2080

...Number of nodes: 7217

...Decompose to 2 CPU domains

...Element load balance ratio = 1.000

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 1.0000

NUMBER OF SUBSTEPS. . . . . . . . . . . . . . . 1

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS. . . . . . . . . . . .ALL DATA WRITTEN

FOR THE LAST SUBSTEP

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

*** NOTE *** CP = 2.969 TIME= 13:25:01

The PCG solver has automatically set the level of difficulty for this

model to 1.

*********** PRECISE MASS SUMMARY ***********

TOTAL RIGID BODY MASS MATRIX ABOUT ORIGIN

Translational mass | Coupled translational/rotational mass

0.65094E-01 0.0000 0.0000 | 0.0000 0.65094 -0.53680E-11

0.0000 0.65094E-01 0.0000 | -0.65094 0.0000 -0.57738E-11

0.0000 0.0000 0.65094E-01 | 0.53680E-11 0.57738E-11 0.0000

------------------------------------------ | ------------------------------------------

| Rotational mass (inertia)

| 8.7442 -0.70490E-09 0.57739E-10

| -0.70490E-09 8.7442 -0.53680E-10

| 0.57739E-10 -0.53680E-10 0.13019

TOTAL MASS = 0.65094E-01

The mass principal axes coincide with the global Cartesian axes

CENTER OF MASS (X,Y,Z)= -0.88701E-10 0.82466E-10 10.000

TOTAL INERTIA ABOUT CENTER OF MASS

2.2349 -0.70490E-09 0.63345E-16

-0.70490E-09 2.2349 0.15416E-17

0.63345E-16 0.15416E-17 0.13019

The inertia principal axes coincide with the global Cartesian axes

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 0.650935E-01

Range of element maximum matrix coefficients in global coordinates

Maximum = 15330356.9 at element 1076.

Minimum = 7051021.31 at element 980.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 1520 SOLID186 0.203 0.000134

2 560 SURF154 0.031 0.000056

Time at end of element matrix formulation CP = 3.203125.

DISTRIBUTED PCG SOLVER SOLUTION CONVERGED

DISTRIBUTED PCG SOLVER SOLUTION STATISTICS

NUMBER OF ITERATIONS= 183

NUMBER OF EQUATIONS = 21651

LEVEL OF CONVERGENCE= 1

CALCULATED NORM = 0.88724E-08

SPECIFIED TOLERANCE = 0.10000E-07

TOTAL CPU TIME (sec)= 0.25

TOTAL WALL TIME(sec)= 0.56

TOTAL MEMORY (GB) = 0.02

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 1520 SOLID186 0.047 0.000031

2 560 SURF154 0.000 0.000000

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 1520 SOLID186 0.031 0.000021

2 560 SURF154 0.000 0.000000

*** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 1

*** TIME = 1.00000 TIME INC = 1.00000 NEW TRIANG MATRIX

*** MAPDL BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

1.562 MB WRITTEN ON RESULTS FILE: file0.rst

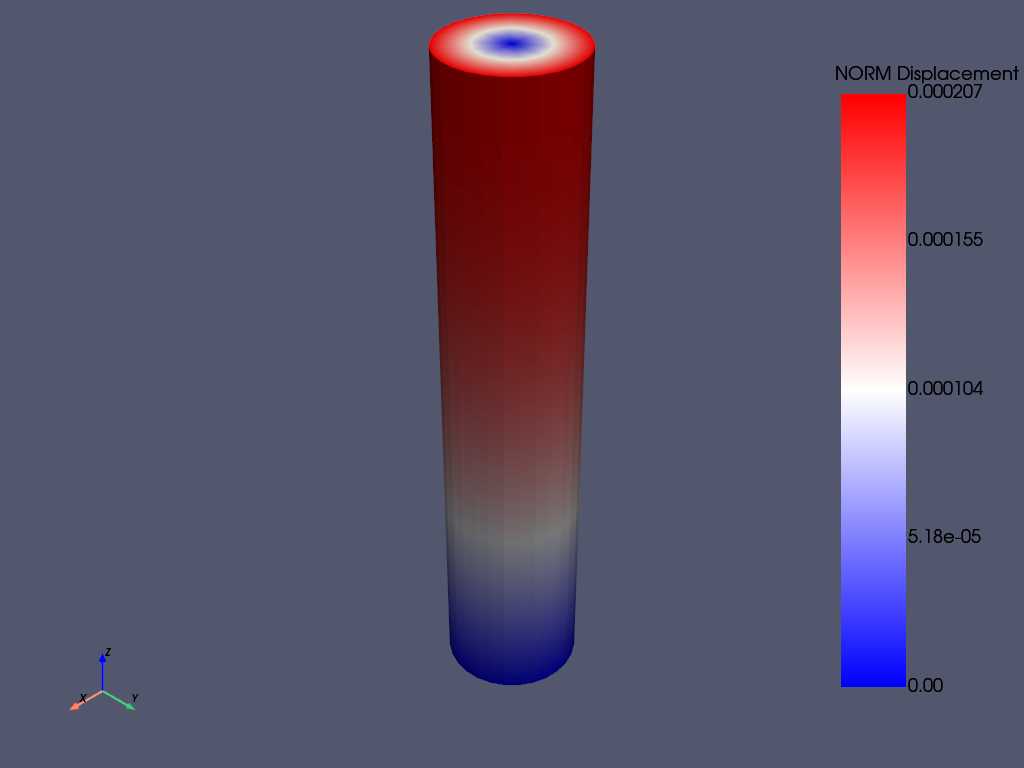

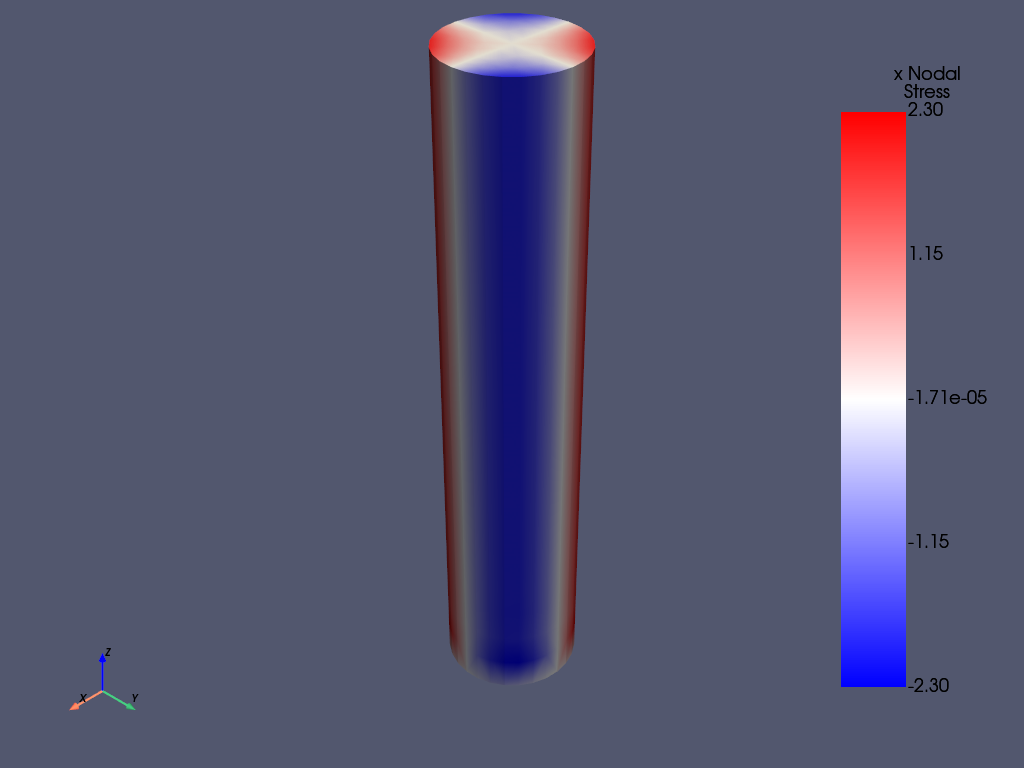

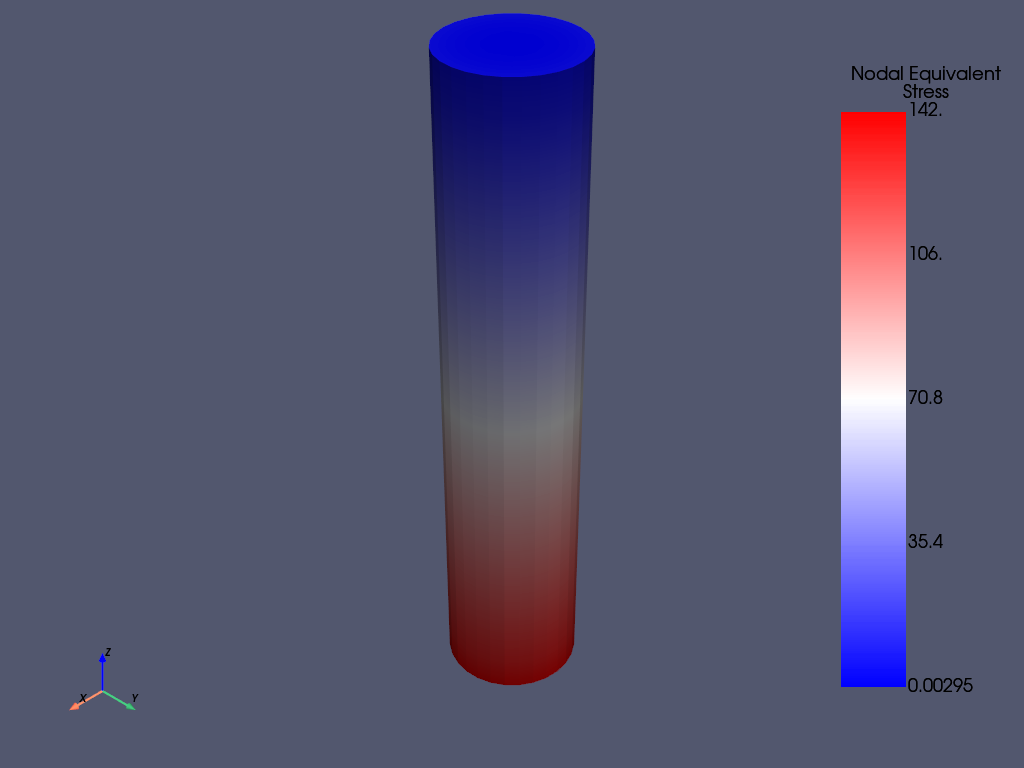

Post-processing#

# Enter post-processor

mapdl.post1()

# Select the step you want to analyse

mapdl.set(1, 1)

USE LOAD STEP 1 SUBSTEP 1 FOR LOAD CASE 0

SET COMMAND GOT LOAD STEP= 1 SUBSTEP= 1 CUMULATIVE ITERATION= 1

TIME/FREQUENCY= 1.0000

TITLE=

Access element results as arrays

nodal_stress = mapdl.post_processing.nodal_stress_intensity()

elem_stress = mapdl.post_processing.element_stress("int")

print("Nodal stress : ", nodal_stress)

print("Element stress : ", elem_stress)

Nodal stress : [1.40063661 1.24138342 1.70598858 ... 0. 0. 0. ]

Element stress : [139.73498821 132.17431724 124.98839965 ... 0. 0.

0. ]

Plot interactively#

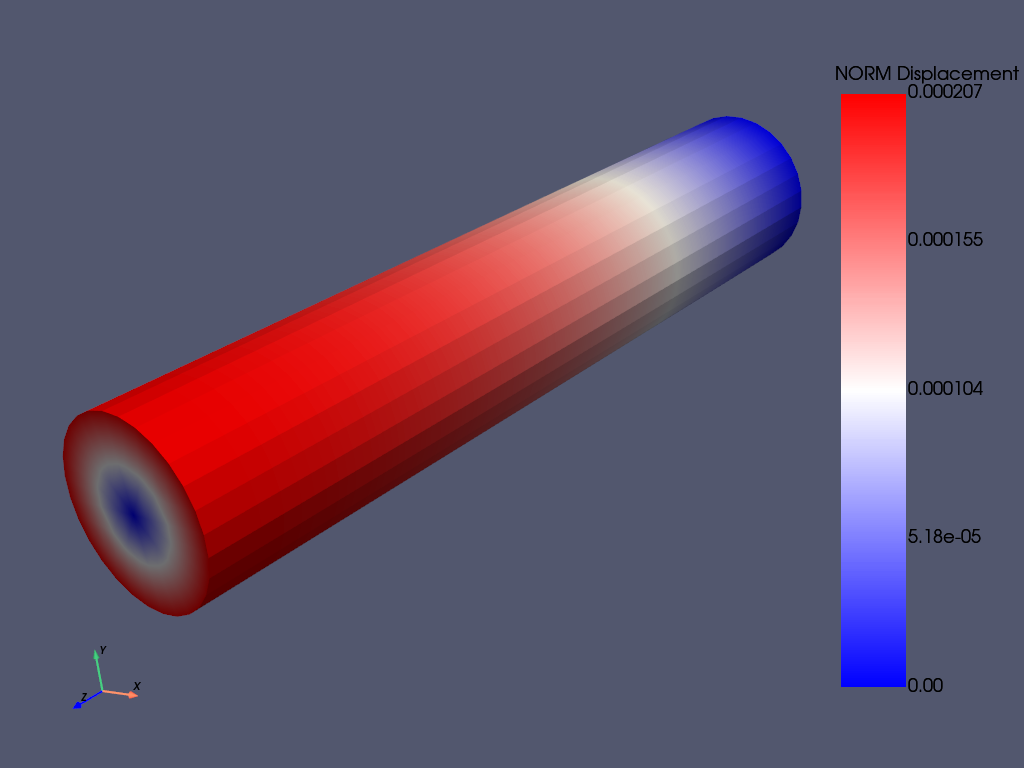

mapdl.post_processing.plot_nodal_displacement(cmap="bwr")

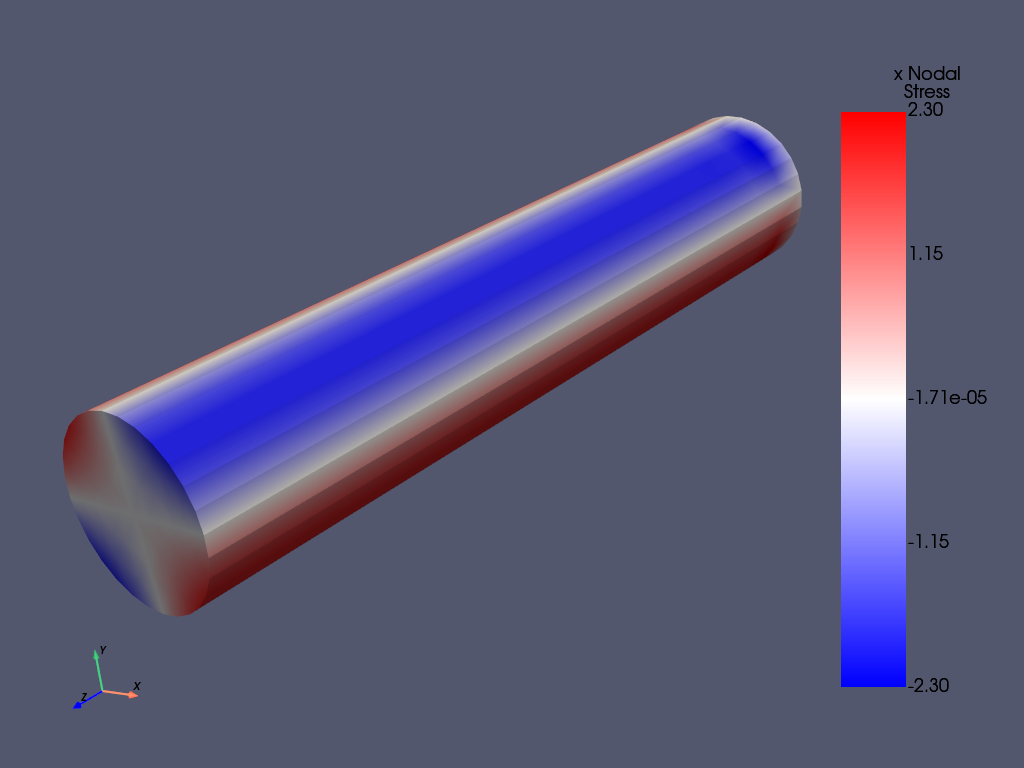

mapdl.post_processing.plot_nodal_component_stress("x", cmap="bwr")

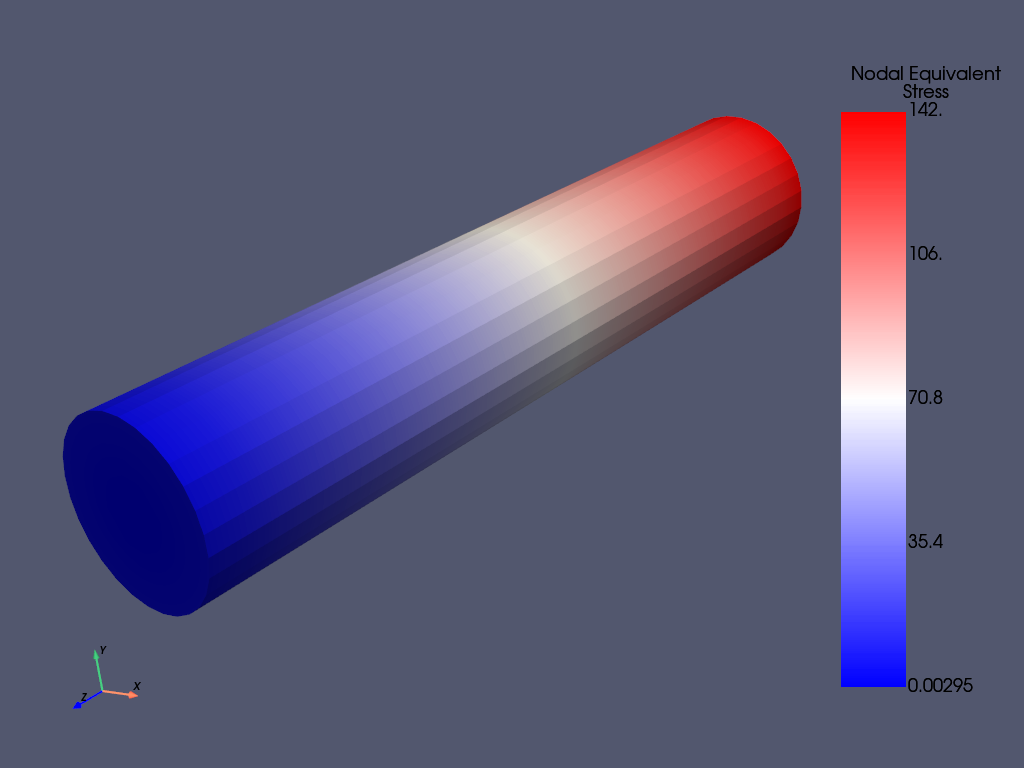

mapdl.post_processing.plot_nodal_eqv_stress(cmap="bwr")

Plot non-interactively#

# Setting up the correct camera angle

cpos = [

(20.992831318277517, 9.78629316586435, 31.905115108541928),

(0.35955395443745797, -1.4198191001571547, 10.346158032932495),

(-0.10547549888485548, 0.9200673323892437, -0.377294345312956),

]

mapdl.post_processing.plot_nodal_displacement(

cmap="bwr", cpos=cpos, savefig="cylinder_disp.png"

)

mapdl.post_processing.plot_nodal_component_stress(

"x", cmap="bwr", cpos=cpos, savefig="cylinder_comp_stx.png"

)

mapdl.post_processing.plot_nodal_eqv_stress(

cmap="bwr", cpos=cpos, savefig="cylinder_eqv_st.png"

)

Stop MAPDL

mapdl.finish()

mapdl.exit()

Total running time of the script: (0 minutes 9.336 seconds)