Note

Go to the end to download the full example code

Running an input file - spotweld SHELL181 example#

This MAPDL example demonstrates how to model spot welding on three thin sheets of metal. Here, the full input file is simply run using the PyMAPDL interface.

Using the following commands, you can directly use an APDL script within a PyMAPDL session with the following commands:

Script initialization#

from ansys.mapdl.core import launch_mapdl

from ansys.mapdl.core.examples.downloads import download_example_data

mapdl = launch_mapdl()

Download and run an MAPDL script#

spotweld_data = download_example_data(

filename="spotweld.inp", directory="pymapdl/spotweld"

)

mapdl.input(spotweld_data)

"\n /INPUT FILE= C:\\Users\\ff\\AppData\\Local\\Ansys\\ansys_mapdl_core\\examples\\spotweld.inp LINE= 0\n\n *** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***\n Ansys Mechanical Enterprise \n 20120530 VERSION=WINDOWS x64 13:24:46 MAR 15, 2024 CP= 0.156\n\n \n\n\n\n ***** MAPDL ANALYSIS DEFINITION (PREP7) *****\n\n NUMBER KEY SET TO 0 -1=NONE 0=BOTH 1=COLOR 2=NUMBER\n\n AREA NUMBERING KEY = 1\n\n KEYPOINT 1 X,Y,Z= 2.00000 10.0000 0.00000 IN CSYS= 0\n\n KEYPOINT 2 X,Y,Z= 10.0000 10.0000 0.00000 IN CSYS= 0\n\n KEYPOINT 3 X,Y,Z= 10.0000 0.150000 0.00000 IN CSYS= 0\n\n KEYPOINT 4 X,Y,Z= 14.0000 0.150000 0.00000 IN CSYS= 0\n\n LINE CONNECTS KEYPOINTS 1 2\n LINE NO.= 1 KP1= 1 TAN1= -1.0000 0.0000 0.0000\n KP2= 2 TAN2= 1.0000 0.0000 0.0000\n\n LINE CONNECTS KEYPOINTS 2 3\n LINE NO.= 2 KP1= 2 TAN1= 0.0000 1.0000 0.0000\n KP2= 3 TAN2= 0.0000 -1.0000 0.0000\n\n LINE CONNECTS KEYPOINTS 3 4\n LINE NO.= 3 KP1= 3 TAN1= -1.0000 0.0000 0.0000\n KP2= 4 TAN2= 1.0000 0.0000 0.0000\n\n FILLET BETWEEN LINES 1 2 RADIUS= 3.0000 \n CENTER KEYPOINT= 0\n LINE NO.= 4 KP1= 5 TAN1= -1.0000 -0.0000 0.0000\n KP2= 6 TAN2= -0.0000 -1.0000 0.0000\n\n FILLET BETWEEN LINES 2 3 RADIUS= 2.0000 \n CENTER KEYPOINT= 0\n LINE NO.= 5 KP1= 7 TAN1= -0.0000 1.0000 0.0000\n KP2= 8 TAN2= 1.0000 0.0000 0.0000\n\n KEYPOINT 9 X,Y,Z= 0.00000 0.00000 0.00000 IN CSYS= 0\n\n KEYPOINT 10 X,Y,Z= 11.0000 0.00000 0.00000 IN CSYS= 0\n\n KEYPOINT 11 X,Y,Z= 15.0000 0.00000 0.00000 IN CSYS= 0\n\n LINE CONNECTS KEYPOINTS 9 10\n LINE NO.= 6 KP1= 9 TAN1= -1.0000 0.0000 0.0000\n KP2= 10 TAN2= 1.0000 0.0000 0.0000\n\n LINE CONNECTS KEYPOINTS 10 11\n LINE NO.= 7 KP1= 10 TAN1= -1.0000 0.0000 0.0000\n KP2= 11 TAN2= 1.0000 0.0000 0.0000\n\n KEYPOINT 12 X,Y,Z= 0.00000 10.0000 0.00000 IN CSYS= 0\n\n SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 6 TO 7 STEP 1\n\n 2 LINES (OF 7 DEFINED) SELECTED BY LSEL COMMAND.\n\n ROTATE LINES 6, 7,\n ABOUT THE AXIS DEFINED BY KEYPOINTS 9 12\n DEGREES OF ARC= 12.00 NUMBER OF SEGMENTS= 1\n\n SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 1 TO 5 STEP 1\n\n 5 LINES (OF 11 DEFINED) SELECTED BY LSEL COMMAND.\n\n ROTATE LINES 1, 2, 3, 4, 5,\n ABOUT THE AXIS DEFINED BY KEYPOINTS 9 12\n DEGREES OF ARC= 12.00 NUMBER OF SEGMENTS= 1\n\n REVERSE THE NORMAL DIRECTION OF AREA(S) 1\n AND MAKE ANY AREA ELEMENTS CONSISTENT WITH THE NEW NORMAL DIRECTION(S).\n\n REVERSE THE NORMAL DIRECTION OF AREA(S) 2\n AND MAKE ANY AREA ELEMENTS CONSISTENT WITH THE NEW NORMAL DIRECTION(S).\n\n SELECT FOR ITEM=AREA COMPONENT= \n IN RANGE 3 TO 7 STEP 1\n\n 5 AREAS (OF 7 DEFINED) SELECTED BY ASEL COMMAND.\n\n SYMMETRY TRANSFORMATION OF AREAS USING COMPONENT Y \n SET IS ALL SELECTED AREAS \n\n SELECT ALL ENTITIES OF TYPE= ALL AND BELOW\n\n GENERATE HARD POINT ON AREA 7 WITH X,Y,Z= 12.9000 0.150000 -1.36000 IN CSYS= 0\n ASSIGN TO HARD POINT 33\n\n HARDPOINT 33 X,Y,Z= 12.9000 0.150000 -1.36000 IN CSYS= 0\n\n view point for window 1 1.0000 1.0000 1.0000 \n\n PLOT AREAS FROM 1 TO 12 BY 1\n\n CUMULATIVE DISPLAY NUMBER 1 WRITTEN TO FILE file000.png - RASTER MODE.\n DISPLAY TITLE= \n \n\n PLOT LINES FROM 1 TO 38 BY 1\n\n CUMULATIVE DISPLAY NUMBER 1 WRITTEN TO FILE file000.png - RASTER MODE.\n DISPLAY TITLE= \n \n\n PLOT KEY POINTS FROM 1 TO 33 BY 1\n\n CUMULATIVE DISPLAY NUMBER 1 WRITTEN TO FILE file000.png - RASTER MODE.\n DISPLAY TITLE= \n \n\n ELEMENT TYPE 1 IS SHELL181 4-NODE SHELL \n KEYOPT( 1- 6)= 0 0 0 0 0 0\n KEYOPT( 7-12)= 0 0 0 0 0 0\n KEYOPT(13-18)= 0 0 0 0 0 0\n\n CURRENT NODAL DOF SET IS UX UY UZ ROTX ROTY ROTZ\n THREE-DIMENSIONAL MODEL\n\n REAL CONSTANT SET 1 ITEMS 1 TO 6\n 0.15000 0.0000 0.0000 0.0000 0.0000 0.0000 \n\n REAL CONSTANT SET 2 ITEMS 1 TO 6\n 0.10000 0.0000 0.0000 0.0000 0.0000 0.0000 \n\n MATERIAL 1 EX = 0.3000000E+08 \n\n MATERIAL 1 PRXY = 0.3000000 \n\n DEFAULT ELEMENT DIVISIONS PER LINE BASED ON ELEMENT SIZE = 0.250 \n\n REAL CONSTANT NUMBER= 1\n\n GENERATE NODES AND ELEMENTS\n IN AREAS 1 TO 1 IN STEPS OF 1\n ** AREA 1 MESHED WITH 197 QUADRILATERALS, 2 TRIANGLES **\n\n NUMBER OF AREAS MESHED = 1\n MAXIMUM NODE NUMBER = 248\n MAXIMUM ELEMENT NUMBER = 199\n\n GENERATE NODES AND ELEMENTS\n IN AREAS 2 TO 2 IN STEPS OF 1\n ** AREA 2 MESHED WITH 177 QUADRILATERALS, 1 TRIANGLES **\n\n NUMBER OF AREAS MESHED = 1\n MAXIMUM NODE NUMBER = 443\n MAXIMUM ELEMENT NUMBER = 377\n\n REAL CONSTANT NUMBER= 2\n\n SELECT FOR ITEM=AREA COMPONENT= \n IN RANGE 3 TO 12 STEP 1\n\n 10 AREAS (OF 12 DEFINED) SELECTED BY ASEL COMMAND.\n\n GENERATE NODES AND ELEMENTS IN ALL SELECTED AREAS \n ** AREA 3 MESHED WITH 124 QUADRILATERALS, 0 TRIANGLES **\n ** AREA 4 MESHED WITH 121 QUADRILATERALS, 1 TRIANGLES **\n ** AREA 5 MESHED WITH 180 QUADRILATERALS, 0 TRIANGLES **\n ** AREA 6 MESHED WITH 152 QUADRILATERALS, 0 TRIANGLES **\n ** AREA 7 MESHED WITH 100 QUADRILATERALS, 1 TRIANGLES **\n ** AREA 8 MESHED WITH 124 QUADRILATERALS, 0 TRIANGLES **\n ** AREA 9 MESHED WITH 121 QUADRILATERALS, 1 TRIANGLES **\n ** AREA 10 MESHED WITH 180 QUADRILATERALS, 0 TRIANGLES **\n ** AREA 11 MESHED WITH 152 QUADRILATERALS, 0 TRIANGLES **\n ** AREA 12 MESHED WITH 91 QUADRILATERALS, 1 TRIANGLES **\n\n NUMBER OF AREAS MESHED = 10\n MAXIMUM NODE NUMBER = 1966\n MAXIMUM ELEMENT NUMBER = 1726\n\n SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 1 TO 9 STEP 1\n\n 9 LINES (OF 38 DEFINED) SELECTED BY LSEL COMMAND.\n\n ALSO SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 12 TO 17 STEP 1\n\n 15 LINES (OF 38 DEFINED) SELECTED BY LSEL COMMAND.\n\n ALSO SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 26 TO 38 STEP 3\n\n 20 LINES (OF 38 DEFINED) SELECTED BY LSEL COMMAND.\n\n ALSO SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 24 TO 36 STEP 3\n\n 25 LINES (OF 38 DEFINED) SELECTED BY LSEL COMMAND.\n\n SELECT ALL NODES (INTERIOR TO LINE, AND AT KEYPOINTS)\n RELATED TO SELECTED LINE SET.\n\n 446 NODES (OF 1966 DEFINED) SELECTED FROM \n 25 SELECTED LINES BY NSLL COMMAND.\n\n SET SNAP FOR WORKING PLANE TO 0.50000E-01\n\n SET GRID SPACING FOR WORKING PLANE TO 0.10000 \n\n SET WP COORDINATE SYSTEM TYPE TO CARTESIAN.\n\n TURN WORKING PLANE GRID AND TRIAD ON.\n\n SET SNAP ANGLE FOR WORKING PLANE TO 5.0000 \n\n SET WORKING PLANE'S TOLERANCE TO 0.30000E-02\n\n *** NOTE *** CP = 0.281 TIME= 13:24:46\n The Working Plane cannot be displayed in NON-UI mode. \n Command Ignored. \n\n ROTATE WORKING PLANE \n 0.0000 DEGREES ABOUT WORKING PLANE'S Z AXIS (X TOWARDS Y)\n -90.000 DEGREES ABOUT WORKING PLANE'S X AXIS (Y TOWARDS Z)\n 0.0000 DEGREES ABOUT WORKING PLANE'S Y AXIS (Z TOWARDS X)\n\n ACTIVE COORDINATE SYSTEM SET TO 11 (CYLINDRICAL)\n WITH PARAMETERS 1.000 AND 1.000 \n\n ACTIVE COORDINATE SYSTEM SET TO 11 (CYLINDRICAL)\n\n IN COORDINATE SYSTEM 11, ROTATE ALL SELECTED NODES.\n\n SPECIFIED CONSTRAINT UY FOR SELECTED NODES 1 TO 1966 BY 1\n REAL= 0.00000000 IMAG= 0.00000000 \n\n SPECIFIED CONSTRAINT ROTX FOR SELECTED NODES 1 TO 1966 BY 1\n REAL= 0.00000000 IMAG= 0.00000000 \n\n ACTIVE COORDINATE SYSTEM SET TO 0 (CARTESIAN) \n\n SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 23 TO 23 STEP 1\n\n 1 LINES (OF 38 DEFINED) SELECTED BY LSEL COMMAND.\n\n SELECT ALL NODES (INTERIOR TO LINE, AND AT KEYPOINTS)\n RELATED TO SELECTED LINE SET.\n\n 3 NODES (OF 1966 DEFINED) SELECTED FROM \n 1 SELECTED LINES BY NSLL COMMAND.\n\n SPECIFIED CONSTRAINT UZ FOR SELECTED NODES 1 TO 1966 BY 1\n REAL= 0.00000000 IMAG= 0.00000000 \n\n SELECT FOR ITEM=LINE COMPONENT= \n IN RANGE 17 TO 17 STEP 1\n\n 1 LINES (OF 38 DEFINED) SELECTED BY LSEL COMMAND.\n\n SELECT ALL NODES (INTERIOR TO LINE, AND AT KEYPOINTS)\n RELATED TO SELECTED LINE SET.\n\n 3 NODES (OF 1966 DEFINED) SELECTED FROM \n 1 SELECTED LINES BY NSLL COMMAND.\n\n SPECIFIED CONSTRAINT UZ FOR SELECTED NODES 1 TO 1966 BY 1\n REAL= 4.00000000 IMAG= 0.00000000 \n\n SELECT ALL ENTITIES OF TYPE= ALL AND BELOW\n\n view point for window 1 1.0000 1.0000 1.0000 \n\n ELEMENT DISPLAYS USING REAL CONSTANT OR SECTION DATA WITH FACTOR 1.00\n\n SELECT FOR ITEM=KP COMPONENT= \n IN RANGE 33 TO 33 STEP 1\n\n 1 KEYPOINTS (OF 33 DEFINED) SELECTED BY KSEL COMMAND.\n\n SELECT NODES ASSOCIATED WITH SELECTED KEYPOINTS\n\n 1 NODES (OF 1966 DEFINED) SELECTED FROM\n 1 SELECTED KEYPOINTS BY NSLK COMMAND.\n\n *GET SW_NODE FROM NODE ITEM=NUM MAX VALUE= 1202.00000 \n\n\n ***** ROUTINE COMPLETED ***** CP = 0.281\n\n\n\n ***** MAPDL SOLUTION ROUTINE *****\n\n SELECT ALL ENTITIES OF TYPE= ALL AND BELOW\n\n LARGE DEFORMATION ANALYSIS\n\n TIME= 4.0000 \n\n USE 10 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM\n FOR AUTOMATIC TIME STEPPING:\n USE 25 SUBSTEPS AS A MAXIMUM\n USE 5 SUBSTEPS AS A MINIMUM\n\n WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL \n FOR ALL APPLICABLE ENTITIES\n\n FINISH SOLUTION PROCESSING\n\n\n ***** ROUTINE COMPLETED ***** CP = 0.281\n\n\n\n SELECT ALL ENTITIES OF TYPE= ALL AND BELOW\n\n *** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***\n Ansys Mechanical Enterprise \n 20120530 VERSION=WINDOWS x64 13:24:46 MAR 15, 2024 CP= 0.281\n\n \n\n\n\n ***** MAPDL ANALYSIS DEFINITION (PREP7) *****\n\n MATERIAL 2 EX = 0.2800000E+08 \n\n MATERIAL 2 PRXY = 0.3000000 \n \n INPUT SECTION ID NUMBER 2\n INPUT SECTION TYPE BEAM\n INPUT BEAM SECTION SUBTYPE Circular Solid \n INPUT BEAM SECTION NAME \n \n SECTION ID NUMBER IS: 2\n BEAM SECTION TYPE IS: Circular Solid \n BEAM SECTION NAME IS: \n COMPUTED BEAM SECTION DATA SUMMARY:\n Area = 0.19620 \n Iyy = 0.30616E-02\n Iyz =-0.13553E-19\n Izz = 0.30616E-02\n Warping Constant = 0.18172E-36\n Torsion Constant = 0.61233E-02\n Centroid Y =-0.77365E-17\n Centroid Z = 0.24867E-17\n Shear Center Y =-0.61607E-17\n Shear Center Z =-0.34245E-17\n Shear Correction-xy = 0.85691 \n Shear Correction-yz = 0.20793E-15\n Shear Correction-xz = 0.85691 \n \n Beam Section is offset to CENTROID of cross section\n\n ELEMENT TYPE 2 IS BEAM188 3-D 2-NODE BEAM \n KEYOPT( 1- 6)= 0 0 0 0 0 0\n KEYOPT( 7-12)= 0 0 0 0 0 0\n KEYOPT(13-18)= 0 0 0 0 0 0\n\n CURRENT NODAL DOF SET IS UX UY UZ ROTX ROTY ROTZ\n THREE-DIMENSIONAL MODEL\n\n ELEMENT TYPE SET TO 2\n\n MATERIAL NUMBER SET TO 2\n\n SECTION ID NUMBER= 2\n\n ****************************************\n *****CREATE NEW SPOT WELD SET: SWELD1 \n GENERATE SPOT WELD BETWEEN SURFACE (7 ) AND SURFACE (2 ).\n THE FIRST SPOT WELD NODE = 1202\n THE SECOND SPOT WELD NODE WILL BE CREATED\n SPOTWELD RADIUS= 0.50000 \n SEARCHING DISTANCE= 2.0000 \n DEFORMABLE SPOT WELD WILL BE GENERATED. \n CREATED ELEMENT TYPE 3 AS TARGE170\n CREATED ELEMENT TYPE 4 AS CONTA174\n\n REAL CONSTANT SETS 3 AND 4 ARE CREATED\n WITH INFLUENCE RADIUS = 0.50000 AND PINBALL RANGE= 0.50000 \n\n NUMBER OF CONTACT ELEMENTS FOR BOTH SURFACES GENERATED= 275\n\n *** NOTE *** CP = 0.281 TIME= 13:24:46\n Rotational degrees of freedom ROTX+ROTY+ROTZ have been activated for \n pilot node 1967. \n\n *** NOTE *** CP = 0.281 TIME= 13:24:46\n Rotational degrees of freedom ROTX+ROTY+ROTZ have been activated for \n pilot node 1969. \n NEW ELEMENTS 278 ARE CREATED FOR SPOTWELD\n *******END OF SPOT WELD CREATION********\n\n ****************************************\n *****ADD MORE SPOT WELD SURFACES TO SET: SWELD1 \n SEARCHING DISTANCE= 2.0000 ,\n ADD NEW SPOT WELD SURFACE: 12 \n\n NUMBER OF CONTACT ELEMENTS FOR BOTH SURFACES GENERATED= 92\n\n *** NOTE *** CP = 0.328 TIME= 13:24:47\n Rotational degrees of freedom ROTX+ROTY+ROTZ have been activated for \n pilot node 1970. \n\n\n ***** ROUTINE COMPLETED ***** CP = 0.328\n\n\n\n ***** MAPDL SOLUTION ROUTINE *****\n\n SELECT ALL ENTITIES OF TYPE= ALL AND BELOW\n\n LARGE DEFORMATION ANALYSIS\n\n TIME= 4.0000 \n\n USE 10 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM\n FOR AUTOMATIC TIME STEPPING:\n USE 25 SUBSTEPS AS A MAXIMUM\n USE 5 SUBSTEPS AS A MINIMUM\n\n WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL \n FOR ALL APPLICABLE ENTITIES\n\n *** NOTE *** CP = 0.344 TIME= 13:24:47\n The automatic domain decomposition logic has selected the MESH domain \n decomposition method with 2 processes per solution. \n\n ***** MAPDL SOLVE COMMAND *****\n\n *** NOTE *** CP = 0.344 TIME= 13:24:47\n There is no title defined for this analysis. \n\n *** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***\n ---GIVE SUGGESTIONS ONLY---\n\n ELEMENT TYPE 1 IS SHELL181. IT IS ASSOCIATED WITH ELASTOPLASTIC \n MATERIALS ONLY. KEYOPT(8)=2 IS SUGGESTED AND KEYOPT(3)=2 IS SUGGESTED FOR\n HIGHER ACCURACY OF MEMBRANE STRESSES; OTHERWISE, KEYOPT(3)=0 IS SUGGESTED.\n\n ELEMENT TYPE 2 IS BEAM188 . KEYOPT(3)=2 IS ALWAYS SUGGESTED.\n\n ELEMENT TYPE 2 IS BEAM188 . KEYOPT(15) IS ALREADY SET AS SUGGESTED.\n\n\n\n *** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2023 R1 23.1 ***\n Ansys Mechanical Enterprise \n 20120530 VERSION=WINDOWS x64 13:24:47 MAR 15, 2024 CP= 0.391\n\n \n\n\n\n S O L U T I O N O P T I O N S\n\n PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D \n DEGREES OF FREEDOM. . . . . . UX UY UZ ROTX ROTY ROTZ\n ANALYSIS TYPE . . . . . . . . . . . . . . . . .STATIC (STEADY-STATE)\n NONLINEAR GEOMETRIC EFFECTS . . . . . . . . . .ON\n NEWTON-RAPHSON OPTION . . . . . . . . . . . . .PROGRAM CHOSEN \n GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC \n\n *** NOTE *** CP = 0.391 TIME= 13:24:47\n SHELL181 and SHELL281 will not support real constant input at a future \n release. Please move to section input. \n\n *** NOTE *** CP = 0.391 TIME= 13:24:47\n This nonlinear analysis defaults to using the full Newton-Raphson \n solution procedure. This can be modified using the NROPT command. \n\n *** NOTE *** CP = 0.391 TIME= 13:24:47\n The conditions for direct assembly have been met. No .emat or .erot \n files will be produced. \n\n *** NOTE *** CP = 0.391 TIME= 13:24:47\n Internal nodes from 1971 to 1973 are created. \n 3 internal nodes are used for handling degrees of freedom on pilot \n nodes of rigid target surfaces. \n\n *** NOTE *** CP = 0.391 TIME= 13:24:47\n Internal nodes from 1971 to 1973 are created. \n 3 internal nodes are used for handling degrees of freedom on pilot \n nodes of rigid target surfaces. \n\n *** NOTE *** CP = 0.406 TIME= 13:24:47\n Force-distributed-surface identified by real constant set 3 and \n contact element type 4 has been set up. The pilot node 1967 is used \n to apply the force which connects to other element 2098. Internal MPC \n will be built. \n The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ\n User defined influence range PINB 0.50000 \n ****************************************\n \n\n *** NOTE *** CP = 0.406 TIME= 13:24:47\n Force-distributed-surface identified by real constant set 4 and \n contact element type 4 has been set up. The pilot node 1969 is used \n to apply the force which connects to other element 2004. Internal MPC \n will be built. \n The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ\n User defined influence range PINB 0.50000 \n ****************************************\n \n\n *** NOTE *** CP = 0.406 TIME= 13:24:47\n Force-distributed-surface identified by real constant set 5 and \n contact element type 4 has been set up. The pilot node 1970 is used \n to apply the force which connects to other element 2004. Internal MPC \n will be built. \n The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ\n User defined influence range PINB 0.50000 \n ****************************************\n \n \n \n\n *** NOTE *** CP = 0.406 TIME= 13:24:47\n Internal nodes from 1971 to 1973 are created. \n 3 internal nodes are used for handling degrees of freedom on pilot \n nodes of rigid target surfaces. \n\n \n \n D I S T R I B U T E D D O M A I N D E C O M P O S E R\n \n ...Number of elements: 2098\n ...Number of nodes: 1973\n ...Decompose to 2 CPU domains\n ...Element load balance ratio = 1.250\n\n\n L O A D S T E P O P T I O N S\n\n LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1\n TIME AT END OF THE LOAD STEP. . . . . . . . . . 4.0000 \n AUTOMATIC TIME STEPPING . . . . . . . . . . . . ON\n INITIAL NUMBER OF SUBSTEPS . . . . . . . . . 10\n MAXIMUM NUMBER OF SUBSTEPS . . . . . . . . . 25\n MINIMUM NUMBER OF SUBSTEPS . . . . . . . . . 5\n MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15\n STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO\n STRESS-STIFFENING . . . . . . . . . . . . . . . ON\n TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT) \n CONVERGENCE CONTROLS. . . . . . . . . . . . . .USE DEFAULTS\n PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT\n DATABASE OUTPUT CONTROLS\n ITEM FREQUENCY COMPONENT\n ALL ALL \n\n\n SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr \n\n *** NOTE *** CP = 0.406 TIME= 13:24:47\n Force-distributed-surface identified by real constant set 4 and \n contact element type 4 has been set up. The pilot node 1969 is used \n to apply the force which connects to other element 2004. Internal MPC \n will be built. \n The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ\n User defined influence range PINB 0.50000 \n ****************************************\n \n\n *** NOTE *** CP = 0.406 TIME= 13:24:47\n Force-distributed-surface identified by real constant set 5 and \n contact element type 4 has been set up. The pilot node 1970 is used \n to apply the force which connects to other element 2004. Internal MPC \n will be built. \n The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ\n User defined influence range PINB 0.50000 \n ****************************************\n \n MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED \n TO BE, NEQIT = 25, BY SOLUTION CONTROL LOGIC. \n\n *** NOTE *** CP = 0.422 TIME= 13:24:47\n Predictor is ON by default for structural elements with rotational \n degrees of freedom. Use the PRED,OFF command to turn the predictor \n OFF if it adversely affects the convergence. \n\n\n Range of element maximum matrix coefficients in global coordinates\n Maximum = 36623388.3 at element 2004. \n Minimum = 1045703.97 at element 1284. \n\n *** ELEMENT MATRIX FORMULATION TIMES\n TYPE NUMBER ENAME TOTAL CP AVE CP\n\n 1 1726 SHELL181 0.062 0.000036\n 2 2 BEAM188 0.000 0.000000\n 3 3 TARGE170 0.000 0.000000\n 4 367 CONTA174 0.000 0.000000\n Time at end of element matrix formulation CP = 0.5. \n\n ALL CURRENT MAPDL DATA WRITTEN TO FILE NAME= file.rdb\n FOR POSSIBLE RESUME FROM THIS POINT\n FORCE CONVERGENCE VALUE = 0.3958E+06 CRITERION= 1979. \n MOMENT CONVERGENCE VALUE = 0.6913E+05 CRITERION= 345.6 \n\n DISTRIBUTED SPARSE MATRIX DIRECT SOLVER.\n Number of equations = 10898, Maximum wavefront = 624\n\n Process memory allocated for solver = 17.389 MB\n Process memory required for in-core solution = 16.783 MB\n Process memory required for out-of-core solution = 12.888 MB\n\n Total memory allocated for solver = 28.418 MB\n Total memory required for in-core solution = 27.413 MB\n Total memory required for out-of-core solution = 20.176 MB\n\n *** NOTE *** CP = 0.609 TIME= 13:24:47\n The Distributed Sparse Matrix Solver is currently running in the \n in-core memory mode. This memory mode uses the most amount of memory \n in order to avoid using the hard drive as much as possible, which most \n often results in the fastest solution time. This mode is recommended \n if enough physical memory is present to accommodate all of the solver \n data. \n Distributed sparse solver maximum pivot= 10401050.5 at node 571 UZ. \n Distributed sparse solver minimum pivot= 46.5108979 at node 1875 ROTZ. \n Distributed sparse solver minimum pivot in absolute value= 46.5108979 \n at node 1875 ROTZ. \n DISP CONVERGENCE VALUE = 0.4000 CRITERION= 0.2000E-01\n EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.4000 \n DISP CONVERGENCE VALUE = 0.4000 CRITERION= 0.2000E-01\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.4000 \n FORCE CONVERGENCE VALUE = 1964. CRITERION= 11.71 \n MOMENT CONVERGENCE VALUE = 11.84 CRITERION= 0.3208 \n EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.9830E-02\n DISP CONVERGENCE VALUE = 0.2164E-02 CRITERION= 0.2000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 0.9997 SCALED MAX DOF INC = -0.9827E-02\n FORCE CONVERGENCE VALUE = 8.933 CRITERION= 11.46 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 0.3296 CRITERION= 0.2967 \n EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.8735E-03\n DISP CONVERGENCE VALUE = 0.8004E-03 CRITERION= 0.2000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.8735E-03\n FORCE CONVERGENCE VALUE = 0.3493 CRITERION= 11.44 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 0.2508E-01 CRITERION= 0.2967 <<< CONVERGED\n >>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 3\n\n *** ELEMENT RESULT CALCULATION TIMES\n TYPE NUMBER ENAME TOTAL CP AVE CP\n\n 1 1726 SHELL181 0.016 0.000009\n 2 2 BEAM188 0.000 0.000000\n 4 367 CONTA174 0.000 0.000000\n\n *** NODAL LOAD CALCULATION TIMES\n TYPE NUMBER ENAME TOTAL CP AVE CP\n\n 1 1726 SHELL181 0.000 0.000000\n 2 2 BEAM188 0.000 0.000000\n 4 367 CONTA174 0.000 0.000000\n *** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 3\n *** TIME = 0.400000 TIME INC = 0.400000 \n *** AUTO STEP TIME: NEXT TIME INC = 0.40000 UNCHANGED\n\n FORCE CONVERGENCE VALUE = 4125. CRITERION= 38.60 \n MOMENT CONVERGENCE VALUE = 39.52 CRITERION= 0.9011 \n DISP CONVERGENCE VALUE = 0.1053E-01 CRITERION= 0.2000E-01 <<< CONVERGED\n EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1250E-01\n DISP CONVERGENCE VALUE = 0.1053E-01 CRITERION= 0.2000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.1250E-01\n FORCE CONVERGENCE VALUE = 131.9 CRITERION= 41.27 \n MOMENT CONVERGENCE VALUE = 3.054 CRITERION= 0.9635 \n EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.4881E-02\n DISP CONVERGENCE VALUE = 0.4881E-02 CRITERION= 0.2000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = -0.4881E-02\n FORCE CONVERGENCE VALUE = 4.675 CRITERION= 40.60 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 0.1712 CRITERION= 0.9479 <<< CONVERGED\n\n *** WARNING *** CP = 0.797 TIME= 13:24:47\n A reference moment value times the tolerance is used by the \n Newton-Raphson method for checking convergence. The calculated \n reference MOMENT CONVERGENCE VALUE = 99.5650837 is less than a \n threshold. This threshold is internally calculated. You can \n overwrite it by specifying MINREF on the CNVTOL command. Check \n results carefully. \n >>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 2\n *** LOAD STEP 1 SUBSTEP 2 COMPLETED. CUM ITER = 5\n *** TIME = 0.800000 TIME INC = 0.400000 \n *** AUTO TIME STEP: NEXT TIME INC = 0.60000 INCREASED (FACTOR = 1.5000)\n\n FORCE CONVERGENCE VALUE = 8067. CRITERION= 108.2 \n MOMENT CONVERGENCE VALUE = 98.52 CRITERION= 2.525 \n DISP CONVERGENCE VALUE = 0.2712E-01 CRITERION= 0.3000E-01 <<< CONVERGED\n EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.2712E-01\n DISP CONVERGENCE VALUE = 0.2712E-01 CRITERION= 0.3000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = -0.2712E-01\n FORCE CONVERGENCE VALUE = 318.7 CRITERION= 110.3 \n MOMENT CONVERGENCE VALUE = 8.860 CRITERION= 2.575 \n EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.6290E-01\n DISP CONVERGENCE VALUE = 0.5985E-01 CRITERION= 0.3000E-01\n LINE SEARCH PARAMETER = 0.9514 SCALED MAX DOF INC = -0.5985E-01\n FORCE CONVERGENCE VALUE = 30.05 CRITERION= 109.0 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 0.7421 CRITERION= 2.545 <<< CONVERGED\n EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.8672E-02\n DISP CONVERGENCE VALUE = 0.8672E-02 CRITERION= 0.3000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.8672E-02\n FORCE CONVERGENCE VALUE = 0.7132 CRITERION= 108.9 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 0.4550E-01 CRITERION= 2.543 <<< CONVERGED\n >>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 3\n *** LOAD STEP 1 SUBSTEP 3 COMPLETED. CUM ITER = 8\n *** TIME = 1.40000 TIME INC = 0.600000 \n *** AUTO TIME STEP: NEXT TIME INC = 0.80000 INCREASED (FACTOR = 1.3333)\n\n FORCE CONVERGENCE VALUE = 0.1684E+05 CRITERION= 241.9 \n MOMENT CONVERGENCE VALUE = 226.0 CRITERION= 5.646 \n DISP CONVERGENCE VALUE = 0.2194 CRITERION= 0.4000E-01\n EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.2194 \n DISP CONVERGENCE VALUE = 0.2187 CRITERION= 0.4000E-01\n LINE SEARCH PARAMETER = 0.9970 SCALED MAX DOF INC = -0.2187 \n FORCE CONVERGENCE VALUE = 659.7 CRITERION= 236.1 \n MOMENT CONVERGENCE VALUE = 14.50 CRITERION= 5.513 \n EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.3210E-01\n DISP CONVERGENCE VALUE = 0.3210E-01 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.3210E-01\n FORCE CONVERGENCE VALUE = 197.5 CRITERION= 234.1 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 11.68 CRITERION= 5.465 \n EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.7983E-02\n DISP CONVERGENCE VALUE = 0.7983E-02 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.7983E-02\n FORCE CONVERGENCE VALUE = 2.890 CRITERION= 234.1 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 0.2515 CRITERION= 5.464 <<< CONVERGED\n >>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 3\n *** LOAD STEP 1 SUBSTEP 4 COMPLETED. CUM ITER = 11\n *** TIME = 2.20000 TIME INC = 0.800000 \n *** AUTO STEP TIME: NEXT TIME INC = 0.80000 UNCHANGED\n\n FORCE CONVERGENCE VALUE = 0.2086E+05 CRITERION= 403.0 \n MOMENT CONVERGENCE VALUE = 271.6 CRITERION= 9.408 \n DISP CONVERGENCE VALUE = 0.5811E-01 CRITERION= 0.4000E-01\n EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.5811E-01\n DISP CONVERGENCE VALUE = 0.5811E-01 CRITERION= 0.4000E-01\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.5811E-01\n FORCE CONVERGENCE VALUE = 548.7 CRITERION= 394.8 \n MOMENT CONVERGENCE VALUE = 21.80 CRITERION= 9.217 \n EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.1339E-01\n DISP CONVERGENCE VALUE = 0.1339E-01 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = -0.1339E-01\n FORCE CONVERGENCE VALUE = 71.38 CRITERION= 392.3 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 1.081 CRITERION= 9.159 <<< CONVERGED\n >>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 2\n *** LOAD STEP 1 SUBSTEP 5 COMPLETED. CUM ITER = 13\n *** TIME = 3.00000 TIME INC = 0.800000 \n *** AUTO TIME STEP: NEXT TIME INC = 0.50000 DECREASED (FACTOR = 0.6250)\n\n FORCE CONVERGENCE VALUE = 0.1149E+05 CRITERION= 510.1 \n MOMENT CONVERGENCE VALUE = 131.9 CRITERION= 11.91 \n DISP CONVERGENCE VALUE = 0.2150E-01 CRITERION= 0.4000E-01 <<< CONVERGED\n EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1082 \n DISP CONVERGENCE VALUE = 0.2107E-01 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 0.9799 SCALED MAX DOF INC = 0.1060 \n FORCE CONVERGENCE VALUE = 2280. CRITERION= 499.4 \n MOMENT CONVERGENCE VALUE = 167.0 CRITERION= 11.66 \n EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.2185E-01\n DISP CONVERGENCE VALUE = 0.8542E-02 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.2185E-01\n FORCE CONVERGENCE VALUE = 226.8 CRITERION= 499.3 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 15.07 CRITERION= 11.66 \n EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1811E-01\n DISP CONVERGENCE VALUE = 0.5235E-02 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.1811E-01\n FORCE CONVERGENCE VALUE = 63.20 CRITERION= 497.9 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 4.057 CRITERION= 11.62 <<< CONVERGED\n >>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 3\n *** LOAD STEP 1 SUBSTEP 6 COMPLETED. CUM ITER = 16\n *** TIME = 3.50000 TIME INC = 0.500000 \n *** AUTO STEP TIME: NEXT TIME INC = 0.50000 UNCHANGED\n\n FORCE CONVERGENCE VALUE = 0.1404E+05 CRITERION= 594.0 \n MOMENT CONVERGENCE VALUE = 770.3 CRITERION= 13.87 \n DISP CONVERGENCE VALUE = 0.4300E-01 CRITERION= 0.4000E-01\n EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1080 \n DISP CONVERGENCE VALUE = 0.4300E-01 CRITERION= 0.4000E-01\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.1080 \n FORCE CONVERGENCE VALUE = 3607. CRITERION= 581.1 \n MOMENT CONVERGENCE VALUE = 187.3 CRITERION= 13.57 \n EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.1026 \n DISP CONVERGENCE VALUE = 0.4779E-01 CRITERION= 0.4000E-01\n LINE SEARCH PARAMETER = 0.9764 SCALED MAX DOF INC = -0.1001 \n FORCE CONVERGENCE VALUE = 2573. CRITERION= 566.5 \n MOMENT CONVERGENCE VALUE = 142.4 CRITERION= 13.23 \n EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.2336E-01\n DISP CONVERGENCE VALUE = 0.1206E-01 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.2336E-01\n FORCE CONVERGENCE VALUE = 350.6 CRITERION= 564.9 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 32.40 CRITERION= 13.19 \n EQUIL ITER 4 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.6452E-02\n DISP CONVERGENCE VALUE = 0.2927E-02 CRITERION= 0.4000E-01 <<< CONVERGED\n LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = -0.6452E-02\n FORCE CONVERGENCE VALUE = 51.00 CRITERION= 564.0 <<< CONVERGED\n MOMENT CONVERGENCE VALUE = 6.037 CRITERION= 13.17 <<< CONVERGED\n >>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 4\n *** LOAD STEP 1 SUBSTEP 7 COMPLETED. CUM ITER = 20\n *** TIME = 4.00000 TIME INC = 0.500000 \n\n\n *** MAPDL BINARY FILE STATISTICS\n BUFFER SIZE USED= 16384\n 11.938 MB WRITTEN ON ELEMENT SAVED DATA FILE: file0.esav\n 2.625 MB WRITTEN ON ASSEMBLED MATRIX FILE: file0.full\n 8.938 MB WRITTEN ON RESULTS FILE: file0.rst\n\n FINISH SOLUTION PROCESSING\n\n\n ***** ROUTINE COMPLETED ***** CP = 1.547\n\n\n"

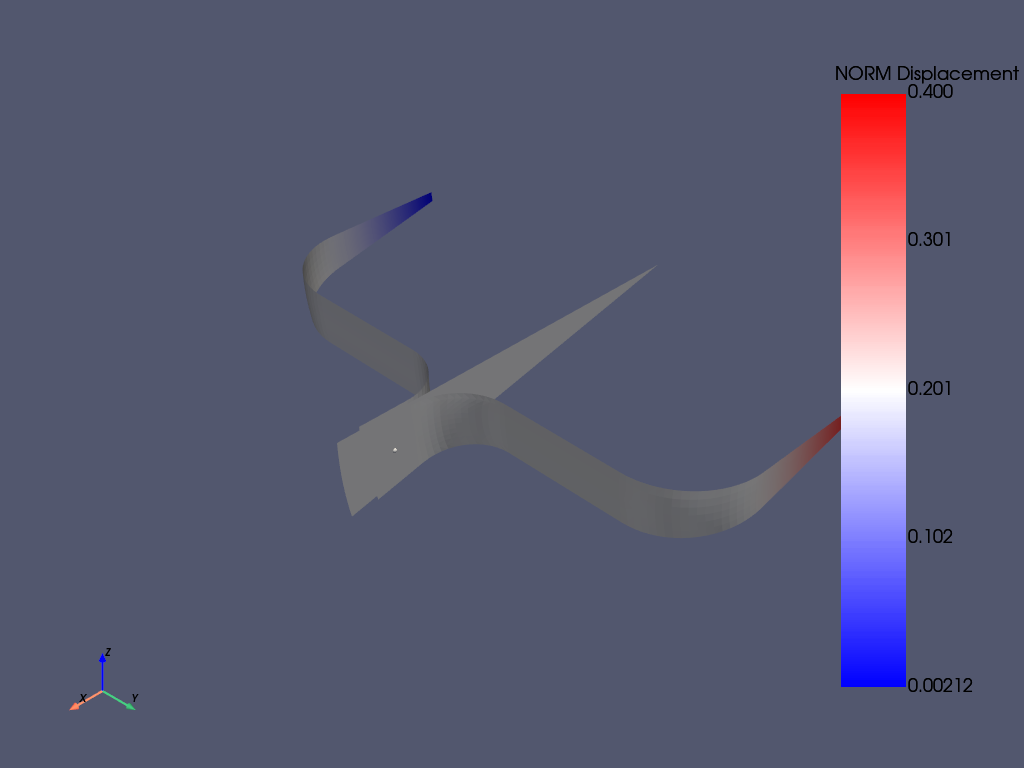

Displacements#

# Enter post-processor

mapdl.post1()

# Plot the time step 1.

mapdl.set(1, 1)

mapdl.post_processing.plot_nodal_displacement(cmap="bwr")

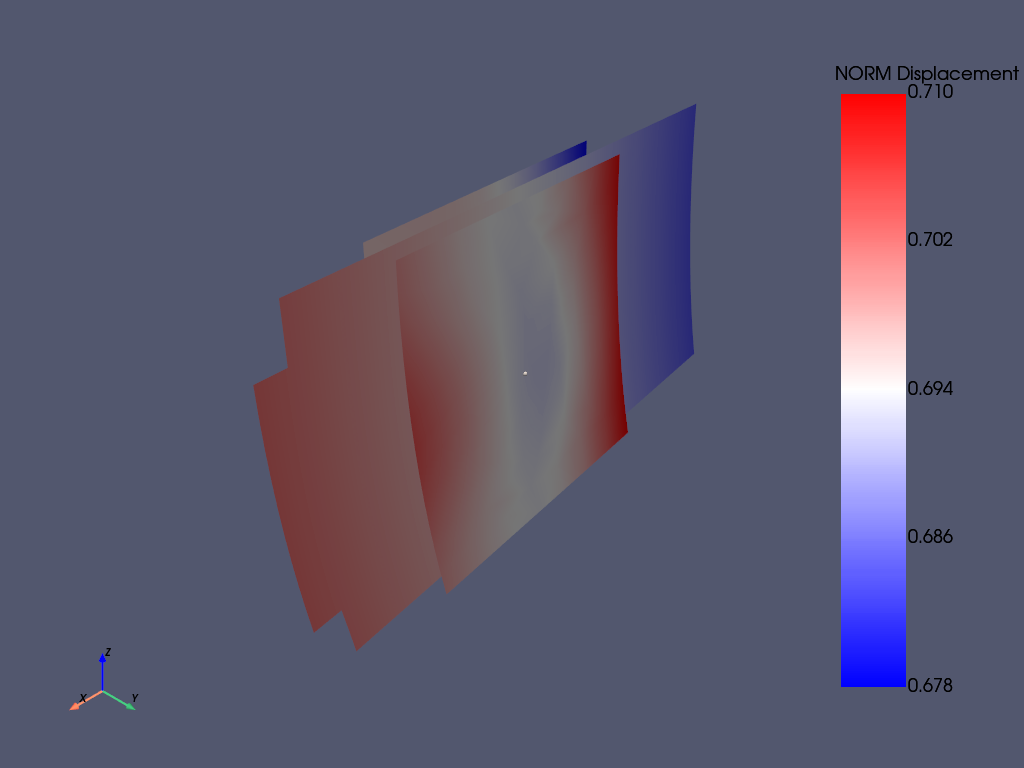

# Plot the time step 3.

mapdl.set(1, 3)

mapdl.post_processing.plot_nodal_displacement(cmap="bwr")

Stress#

# Get the nodal and element component stress at time step 1.

mapdl.set(1, 1)

nodal_stress = mapdl.post_processing.nodal_stress_intensity()

print("Nodal stress : ", nodal_stress)

# Plot the element stress.

element_stress = mapdl.post_processing.element_stress("int")

print("Element stress : ", element_stress)

Nodal stress : [0. 0. 0. ... 0. 0. 0.]

Element stress : [0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.

0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0.]

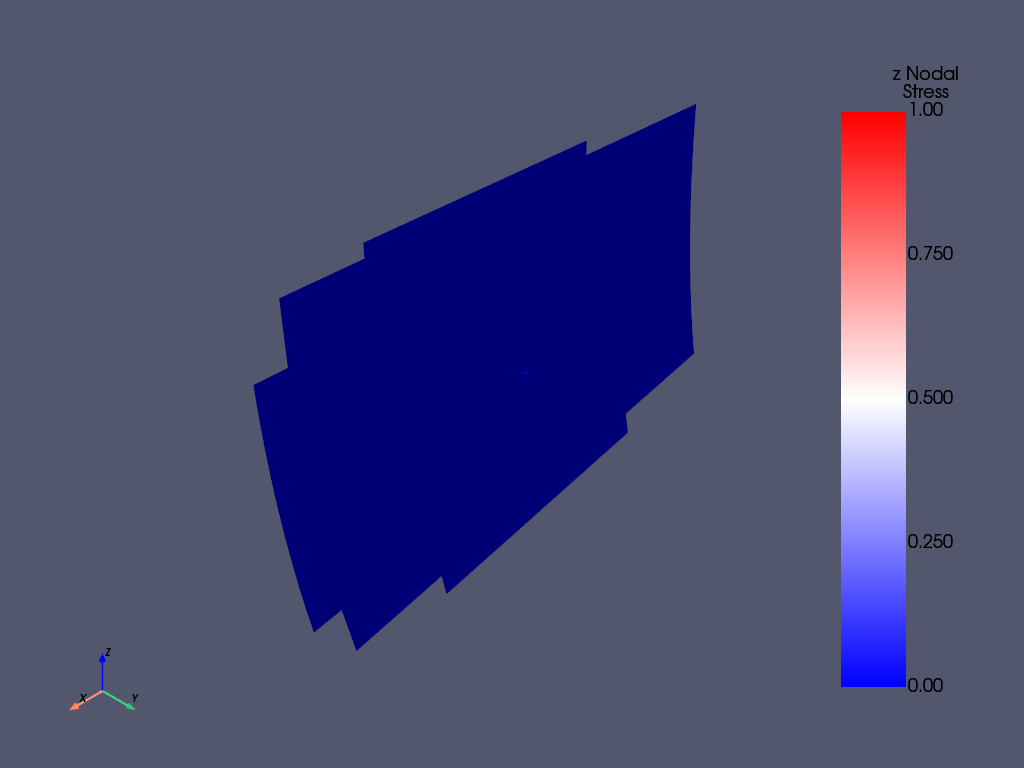

The stress at the contact element simulating the spot weld.

Plot the nodal stress in the Z direction.

mapdl.post_processing.plot_nodal_component_stress("z")

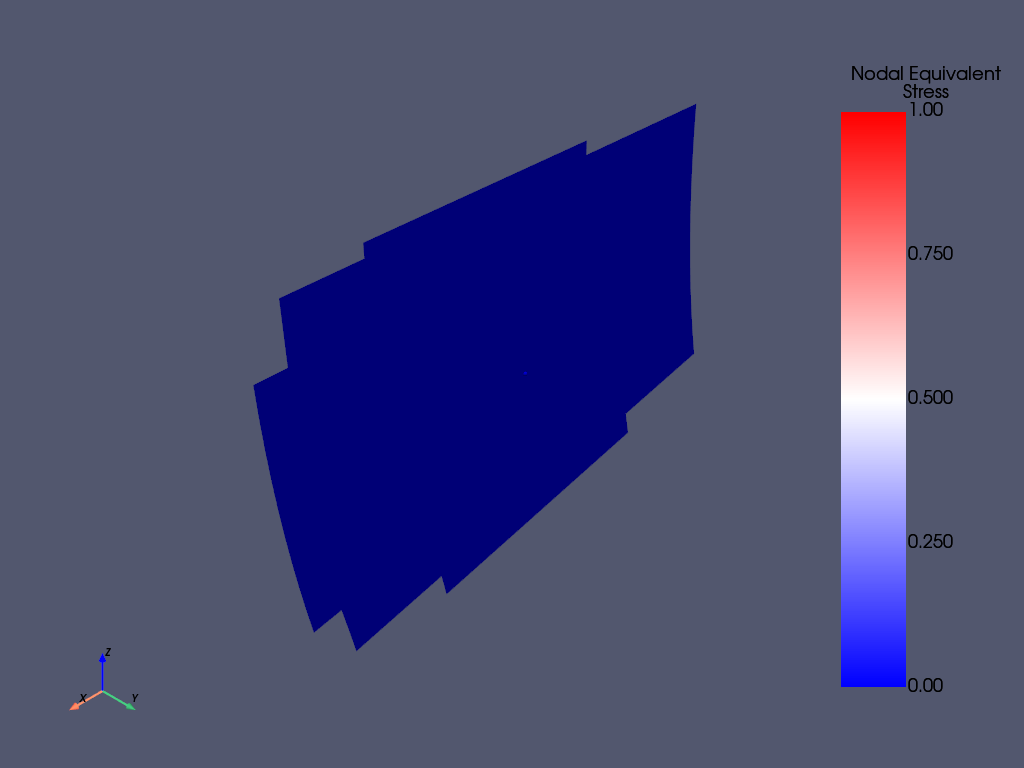

Get the cumulative equivalent stress and plot the von Mises stress.

eqv_stress = mapdl.post_processing.nodal_eqv_stress()

print("Cumulative equivalent stress : ", eqv_stress)

mapdl.post_processing.plot_nodal_eqv_stress()

Cumulative equivalent stress : [0. 0. 0. ... 0. 0. 0.]

Stop MAPDL

mapdl.finish()

mapdl.exit()

Total running time of the script: (0 minutes 7.750 seconds)